Understanding Agricultural Fitting Moulds: Key Insights for Manufacturing Professionals

2025-06-15

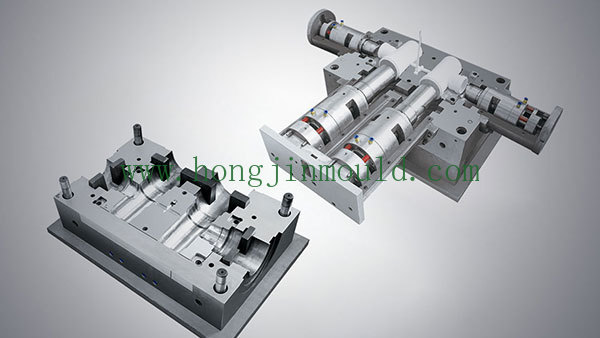

Agricultural fitting moulds are specialized tools used in the manufacturing of plastic components that are essential for various agricultural applications. These moulds are designed to create fittings, connectors, and other components made of durable plastic materials, which are crucial for ensuring the efficient operation of agricultural machinery.

The design of agricultural fitting moulds typically involves a thorough understanding of the specific requirements of the agricultural industry. These requirements may include resistance to harsh environmental conditions, compatibility with different types of agricultural equipment, and the ability to withstand mechanical stress during operation. Therefore, the design process often incorporates advanced engineering techniques and collaboration with agricultural equipment manufacturers to ensure that the moulds meet all necessary specifications.

The manufacturing process of agricultural fitting moulds involves several steps, including material selection, mould fabrication, and quality assurance. The most commonly used materials for these moulds are high-grade steel or aluminum, chosen for their strength and durability. The mould fabrication process may involve methods such as CNC machining, electrical discharge machining (EDM), and injection moulding. Each method has its advantages and can be selected based on the complexity and volume of the components to be produced.

Quality assurance is a critical step in the production of agricultural fitting moulds. It involves rigorous testing to ensure that the moulds produce components that meet the required standards for strength, precision, and durability. This may include dimensional inspections, material testing, and performance evaluations. Ensuring the highest quality in mould production leads to improved efficiency and reliability in agricultural machinery.

Moreover, the trend towards automation and precision agriculture is influencing the development of agricultural fitting moulds. As technology advances, manufacturers are increasingly turning to smart manufacturing practices, incorporating automation and data analytics to enhance production efficiency and reduce lead times. This shift not only improves the overall quality of the moulds but also facilitates quicker adaptation to changing agricultural needs.

In conclusion, agricultural fitting moulds are a vital component in the manufacturing of agricultural machinery. Understanding their design, manufacturing processes, and quality assurance protocols can provide manufacturing professionals with valuable insights to improve their operations. By focusing on innovation and quality, manufacturers can ensure that they meet the evolving demands of the agricultural industry, thus contributing to enhanced productivity and sustainability in farming practices.

The design of agricultural fitting moulds typically involves a thorough understanding of the specific requirements of the agricultural industry. These requirements may include resistance to harsh environmental conditions, compatibility with different types of agricultural equipment, and the ability to withstand mechanical stress during operation. Therefore, the design process often incorporates advanced engineering techniques and collaboration with agricultural equipment manufacturers to ensure that the moulds meet all necessary specifications.

The manufacturing process of agricultural fitting moulds involves several steps, including material selection, mould fabrication, and quality assurance. The most commonly used materials for these moulds are high-grade steel or aluminum, chosen for their strength and durability. The mould fabrication process may involve methods such as CNC machining, electrical discharge machining (EDM), and injection moulding. Each method has its advantages and can be selected based on the complexity and volume of the components to be produced.

Quality assurance is a critical step in the production of agricultural fitting moulds. It involves rigorous testing to ensure that the moulds produce components that meet the required standards for strength, precision, and durability. This may include dimensional inspections, material testing, and performance evaluations. Ensuring the highest quality in mould production leads to improved efficiency and reliability in agricultural machinery.

Moreover, the trend towards automation and precision agriculture is influencing the development of agricultural fitting moulds. As technology advances, manufacturers are increasingly turning to smart manufacturing practices, incorporating automation and data analytics to enhance production efficiency and reduce lead times. This shift not only improves the overall quality of the moulds but also facilitates quicker adaptation to changing agricultural needs.

In conclusion, agricultural fitting moulds are a vital component in the manufacturing of agricultural machinery. Understanding their design, manufacturing processes, and quality assurance protocols can provide manufacturing professionals with valuable insights to improve their operations. By focusing on innovation and quality, manufacturers can ensure that they meet the evolving demands of the agricultural industry, thus contributing to enhanced productivity and sustainability in farming practices.

We provide exceptional products and quality services, ensuring that our products meet the relevant standards of various countries, and earning the trust and support of our customers.

CONTACT

103, Building 10, Lecheng Molding Industrial Park, Xinqian Street, Huangyan District, Taizhou city, Zhejiang Province