Maximizing ROI with Efficient Electrical Conduit Fitting Moulds: A Comprehensive Guide

2025-06-10

Maximizing ROI with Efficient Electrical Conduit Fitting Moulds

Table of Contents

- Introduction to Electrical Conduit Fitting Moulds

- Understanding ROI in Manufacturing

- Key Factors Affecting Efficiency in Mould Production

- Optimizing the Production Process

- The Role of Maintenance in Maximizing ROI

- Real-World Case Studies of Successful ROI Maximization

- Future Trends in Electrical Conduit Fitting Moulds

- Conclusion

Introduction to Electrical Conduit Fitting Moulds

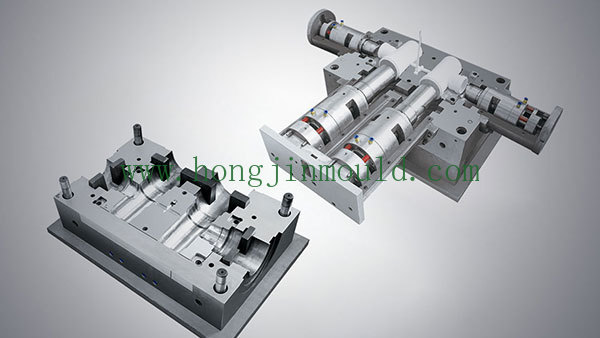

Electric conduit fittings are integral components in electrical installations, ensuring safe and efficient pathway management for electrical wiring. The manufacturing of these fittings relies heavily on precision moulds tailored to meet specific design and functionality standards. Achieving **efficient electrical conduit fitting moulds** is vital to ensure not only the quality of the end product but also the financial viability of the manufacturing operation. This guide explores ways to maximize return on investment (ROI) by focusing on efficiency in mould production.

Understanding ROI in Manufacturing

ROI is a crucial metric for any manufacturing business, indicating the profitability of investments made in production processes. In the context of electrical conduit fitting moulds, maximizing ROI means ensuring that every dollar spent on production translates into higher revenue and reduced costs. This involves evaluating several factors including production time, material costs, and waste management.

Key Factors Affecting Efficiency in Mould Production

To maximize ROI, it is essential to understand the key factors that influence efficiency in mould production.

Mould Design and Its Importance

The design of the mould is a critical aspect that impacts the efficiency of the production process. An optimized mould design can reduce the cycle time and improve the precision of the fittings produced. Factors to consider in mould design include:

- **Complexity**: Simplifying the design can lead to shorter production times.

- **Cooling Systems**: Incorporating effective cooling channels can speed up the production cycle.

- **Material Flow**: Ensuring optimal material flow within the mould can reduce defects and scrap rates.

Material Selection for High Performance

Choosing the right materials for both the mould and the fittings is fundamental to achieving high efficiency. Materials should be durable enough to withstand high-pressure conditions while also being cost-effective. Common materials used in electrical conduit fitting moulds include:

- **Steel**: Known for its durability and strength, steel is often used in high-production environments.

- **Aluminum**: Lighter and easier to machine, aluminum can offer cost advantages in some applications.

- **Specialty Alloys**: These can provide enhanced performance characteristics in specific environments.

Optimizing the Production Process

An optimized production process can significantly reduce costs and increase manufacturing speed. Strategies for optimizing production include:

Integrating Automation into Mould Production

Automation technology has revolutionized manufacturing processes. Implementing automated systems for tasks such as material handling, moulding, and finishing can lead to:

- **Increased Production Rates**: Automation can significantly reduce cycle times.

- **Enhanced Precision**: Automated systems are less prone to human error, resulting in higher-quality products.

- **Labor Cost Reduction**: Fewer manual labor hours required.

Implementing Quality Control Measures

Maintaining high-quality standards is essential for customer satisfaction and minimizing waste. Establishing a rigorous quality control process throughout the production cycle can include:

- **Regular Inspections**: Conducting inspections at various stages of production.

- **Testing for Compliance**: Ensuring that products meet industry standards and specifications.

- **Feedback Loops**: Utilizing feedback from quality assessments to make real-time adjustments.

The Role of Maintenance in Maximizing ROI

Regular maintenance of moulds and production equipment is critical for optimal performance. A well-maintained mould can lead to fewer defects, reduced downtime, and lower repair costs. Implementing a preventive maintenance schedule can:

- **Extend Equipment Life**: Regular attention can prevent major breakdowns.

- **Enhance Efficiency**: Well-maintained equipment operates more smoothly and reliably.

- **Reduce Unexpected Costs**: By anticipating maintenance needs, manufacturers can avoid costly repairs.

Real-World Case Studies of Successful ROI Maximization

Exploring successful case studies can provide valuable insights into effective strategies for maximizing ROI. For instance:

- **Company A: Streamlined Production Process**

Company A revamped its production line by integrating automated moulding systems, resulting in a 30% reduction in cycle times and a 20% increase in output.

- **Company B: Innovative Mould Design**

By redesigning their electrical conduit fitting moulds with improved cooling channels, Company B was able to reduce material waste by 15%, significantly improving their profit margins.

Future Trends in Electrical Conduit Fitting Moulds

As technology advances, the future of electrical conduit fitting moulds is likely to be shaped by several emerging trends:

- **Additive Manufacturing**: This technology promises to revolutionize mould design and production, allowing for more complex geometries and faster prototyping.

- **Sustainability Focus**: Increasing demand for eco-friendly materials and processes will drive innovation in mould manufacturing.

Conclusion

Maximizing ROI with efficient electrical conduit fitting moulds involves a multifaceted approach that includes optimizing mould design, selecting appropriate materials, automating production processes, maintaining high-quality standards, and implementing a robust maintenance schedule. By focusing on these areas, manufacturers can not only enhance their operational efficiency but also significantly improve their profitability in the competitive landscape of electrical conduit fitting production. As the industry evolves, staying ahead of emerging trends will be crucial for ongoing success.

FAQs

1. What are electrical conduit fitting moulds?

Electrical conduit fitting moulds are specialized tools used to shape and form electrical fittings, which are essential for managing electrical wiring systems.

2. How can I improve the efficiency of my mould production process?

You can improve efficiency by focusing on optimal mould design, integrating automation, and implementing strict quality control measures.

3. What materials are best for electrical conduit fitting moulds?

Common materials include steel for durability, aluminum for lighter applications, and specialty alloys for enhanced performance.

4. Why is maintenance important in mould production?

Regular maintenance helps prevent breakdowns, enhances efficiency, and extends the lifespan of your moulds and equipment.

5. What are the latest trends in mould production technology?

Emerging trends include additive manufacturing for complex designs and a growing focus on sustainability in materials and processes.

We provide exceptional products and quality services, ensuring that our products meet the relevant standards of various countries, and earning the trust and support of our customers.

CONTACT

103, Building 10, Lecheng Molding Industrial Park, Xinqian Street, Huangyan District, Taizhou city, Zhejiang Province