Essential Insights into Collapsible Pipe Fitting Moulds for Efficient Plastic Manufacturing

2025-06-05

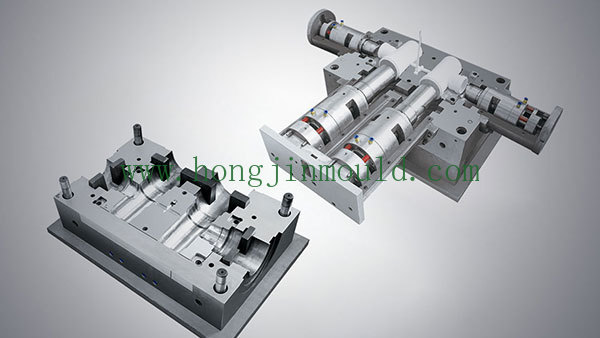

In the realm of plastic manufacturing, collapsible pipe fitting moulds play a crucial role in the efficient production of various components. These specialised moulds are designed to create pipe fittings that can collapse, allowing for increased versatility and ease of use in various applications. Understanding their intricacies can help manufacturers optimize their processes and enhance product quality.

**Design and Functionality**

Collapsible pipe fitting moulds are engineered to produce fittings that can be easily assembled and disassembled. This feature is particularly beneficial in applications where space-saving and portability are essential. The design often incorporates unique mechanisms that allow the fitting to be collapsed without compromising its structural integrity. Manufacturers can achieve intricate shapes and sizes, accommodating different piping systems and ensuring compatibility with various standards.

The mould's design begins with the selection of high-quality materials that can withstand the pressures of injection molding. The choice of material not only affects the durability of the mould but also influences the quality of the finished product. Optimal cooling channels and precise dimensions are crucial in ensuring uniformity and minimizing defects in the produced fittings.

**Production Efficiency**

One of the significant advantages of using collapsible pipe fitting moulds is the efficiency they bring to the manufacturing process. These moulds are designed for quick cycle times, enabling manufacturers to produce large quantities of fittings in a shorter period. The collapsible feature reduces the need for excessive assembly parts, streamlining the production process and reducing labor costs.

Moreover, the use of advanced injection molding technology with collapsible moulds allows for improved surface finishes and reduced post-processing requirements. This efficiency leads to lower waste rates and higher profitability for manufacturers.

**Quality Control and Precision**

Quality control is paramount in any manufacturing process, and collapsible pipe fitting moulds are no exception. The precision of the mould directly impacts the quality of the fittings produced. Implementing rigorous quality assurance protocols throughout the moulding process ensures that each fitting meets high standards of performance and reliability. Regular maintenance and inspection of the mould are essential to prevent wear and tear, which can affect the final product's quality.

In conclusion, collapsible pipe fitting moulds are an integral part of the plastic manufacturing industry, providing versatility, efficiency, and high-quality output. Manufacturers who invest in understanding and utilizing these moulds can significantly enhance their production capabilities and stay competitive in the market. With the right design and operational practices, collapsible pipe fitting moulds can lead to remarkable improvements in both product quality and operational efficiency.

**Design and Functionality**

Collapsible pipe fitting moulds are engineered to produce fittings that can be easily assembled and disassembled. This feature is particularly beneficial in applications where space-saving and portability are essential. The design often incorporates unique mechanisms that allow the fitting to be collapsed without compromising its structural integrity. Manufacturers can achieve intricate shapes and sizes, accommodating different piping systems and ensuring compatibility with various standards.

The mould's design begins with the selection of high-quality materials that can withstand the pressures of injection molding. The choice of material not only affects the durability of the mould but also influences the quality of the finished product. Optimal cooling channels and precise dimensions are crucial in ensuring uniformity and minimizing defects in the produced fittings.

**Production Efficiency**

One of the significant advantages of using collapsible pipe fitting moulds is the efficiency they bring to the manufacturing process. These moulds are designed for quick cycle times, enabling manufacturers to produce large quantities of fittings in a shorter period. The collapsible feature reduces the need for excessive assembly parts, streamlining the production process and reducing labor costs.

Moreover, the use of advanced injection molding technology with collapsible moulds allows for improved surface finishes and reduced post-processing requirements. This efficiency leads to lower waste rates and higher profitability for manufacturers.

**Quality Control and Precision**

Quality control is paramount in any manufacturing process, and collapsible pipe fitting moulds are no exception. The precision of the mould directly impacts the quality of the fittings produced. Implementing rigorous quality assurance protocols throughout the moulding process ensures that each fitting meets high standards of performance and reliability. Regular maintenance and inspection of the mould are essential to prevent wear and tear, which can affect the final product's quality.

In conclusion, collapsible pipe fitting moulds are an integral part of the plastic manufacturing industry, providing versatility, efficiency, and high-quality output. Manufacturers who invest in understanding and utilizing these moulds can significantly enhance their production capabilities and stay competitive in the market. With the right design and operational practices, collapsible pipe fitting moulds can lead to remarkable improvements in both product quality and operational efficiency.

We provide exceptional products and quality services, ensuring that our products meet the relevant standards of various countries, and earning the trust and support of our customers.

CONTACT

103, Building 10, Lecheng Molding Industrial Park, Xinqian Street, Huangyan District, Taizhou city, Zhejiang Province