The Impact of CPVC Pipe Fitting Moulds on the Plastic Industry

2025-05-31

The Impact of CPVC Pipe Fitting Moulds on the Plastic Industry

Table of Contents

- 1. Introduction to CPVC Pipe Fitting Moulds

- 2. Understanding CPVC and Its Applications

- 3. The Mould Manufacturing Process

- 3.1 Designing CPVC Pipe Fitting Moulds

- 3.2 Materials Used in Mould Manufacturing

- 3.3 Machining and Finishing Techniques

- 4. Benefits of Using CPVC Pipe Fitting Moulds

- 5. Environmental Impact of CPVC Moulds

- 6. Challenges in CPVC Mould Manufacturing

- 7. Future Trends in CPVC Mould Technology

- 8. Conclusion

- 9. FAQs

1. Introduction to CPVC Pipe Fitting Moulds

The plastic industry has evolved significantly over the past few decades, driven by technological advancements and a growing demand for durable materials. Among these innovations, **Chlorinated Polyvinyl Chloride (CPVC)** pipe fitting moulds have emerged as a vital component. This article explores their profound impact on the plastic industry, highlighting the manufacturing processes, benefits, and future trends associated with CPVC moulds.

2. Understanding CPVC and Its Applications

CPVC is a thermoplastic produced by chlorinating polyvinyl chloride (PVC) resin. It is renowned for its excellent resistance to corrosion, high temperatures, and chemicals, making it a preferred choice in various applications, including plumbing, industrial piping, and fire protection systems.

2.1 Applications of CPVC

The versatility of CPVC is evident in its applications:

- **Plumbing:** CPVC pipes are commonly used in hot and cold water distribution systems due to their ability to withstand high temperatures.

- **Industrial Applications:** The chemical resistance of CPVC makes it suitable for transporting aggressive fluids in industries like pharmaceuticals and food processing.

- **Fire Sprinkler Systems:** The material’s fire-retardant properties enable its use in life-saving fire protection systems.

3. The Mould Manufacturing Process

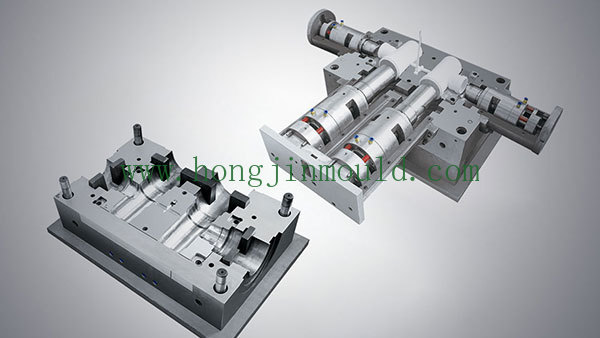

The production of CPVC pipe fitting moulds involves several critical stages. Each stage is essential for ensuring the quality and functionality of the final product.

3.1 Designing CPVC Pipe Fitting Moulds

The design phase is crucial, where engineers use Computer-Aided Design (CAD) software to create intricate mould designs. Factors such as flow characteristics, cooling efficiency, and ease of demoulding are considered. The objective is to design moulds that optimize production efficiency while ensuring the integrity of the pipe fittings.

3.2 Materials Used in Mould Manufacturing

The selection of materials for mould production significantly influences the mould's performance and longevity. High-quality steels, such as P20 and H13, are commonly used for their durability and resistance to wear. Additionally, surface treatments, like nitriding, enhance the lifespan of the moulds, ensuring they can withstand repeated use.

3.3 Machining and Finishing Techniques

After the design and material selection, machining processes, including milling, drilling, and electrical discharge machining (EDM), are employed to achieve precise dimensions. Following machining, finishing processes such as polishing and coating are applied, further enhancing the mould's performance and aesthetic appeal.

4. Benefits of Using CPVC Pipe Fitting Moulds

The adoption of CPVC pipe fitting moulds presents numerous advantages that contribute to their growing popularity in the plastic industry.

4.1 Enhanced Durability

CPVC pipe fittings exhibit exceptional strength and durability, making them resistant to impact and weathering. This results in longer service life and reduced replacement costs.

4.2 Cost-Effectiveness

The long-term cost savings associated with CPVC installations stem from their low maintenance requirements and reduced energy costs due to their insulating properties.

4.3 Versatility in Design

CPVC moulds can be designed to produce a wide variety of fitting sizes and shapes, catering to diverse industry needs. This versatility allows manufacturers to meet specific client requirements efficiently.

4.4 Resistance to Chemical Corrosion

The inherent chemical resistance of CPVC makes it suitable for numerous industrial applications, reducing the risk of pipe failure caused by corrosive substances.

5. Environmental Impact of CPVC Moulds

As sustainability becomes increasingly important, the environmental implications of CPVC production and use must be considered.

5.1 Recycling Potential

CPVC materials can be recycled, promoting a circular economy within the plastics industry. Innovative recycling technologies are being developed to reprocess CPVC waste into new products, minimizing environmental impact.

5.2 Reducing Carbon Footprint

The energy-efficient properties of CPVC contribute to a lower carbon footprint. By requiring less energy to transport hot and cold fluids, CPVC installations help reduce overall energy consumption in buildings.

6. Challenges in CPVC Mould Manufacturing

Despite the many advantages, the production of CPVC moulds is not without challenges.

6.1 Technical Complexity

The manufacturing of high-quality CPVC moulds demands advanced technology and skilled labor. Continuous training and investment in modern equipment are essential to overcoming these challenges.

6.2 Material Limitations

While CPVC is an excellent material for moulds, it does have limitations compared to other thermoplastics. Manufacturers must conduct thorough research to ensure that CPVC is the best choice for specific applications.

7. Future Trends in CPVC Mould Technology

The future of CPVC mould technology looks promising, with ongoing innovations expected to enhance production processes and product quality.

7.1 Automation and Robotics

The integration of automation in mould manufacturing can lead to increased efficiency and reduced production times. Robotic systems can streamline repetitive tasks, allowing manufacturers to focus on design and quality control.

7.2 Advanced Materials

Research into new materials and composites could improve the performance of CPVC moulds, leading to even more durable and cost-effective products.

7.3 Sustainable Practices

The demand for eco-friendly practices will push manufacturers toward adopting more sustainable materials and processes, aligning with global environmental standards.

8. Conclusion

The impact of CPVC pipe fitting moulds on the plastic industry is substantial, shaping how products are designed and manufactured. Their unique properties and benefits make them an invaluable asset across various applications. As technology continues to evolve, the potential for CPVC moulds to enhance efficiency, reduce costs, and minimize environmental impact will only grow, marking a bright future for the plastic industry.

9. FAQs

What is CPVC used for?

CPVC is primarily used in plumbing, industrial applications, and fire protection systems due to its excellent chemical resistance and durability.

How are CPVC pipe fitting moulds manufactured?

The manufacturing process involves designing moulds using CAD software, selecting high-quality materials, and employing precise machining techniques.

What are the advantages of using CPVC over PVC?

CPVC offers superior resistance to higher temperatures and chemicals compared to PVC, making it suitable for more demanding applications.

Can CPVC moulds be recycled?

Yes, CPVC materials can be recycled, promoting sustainable practices in the plastic industry.

What are the future trends in CPVC mould technology?

Future trends include increased automation, the use of advanced materials, and a focus on sustainable manufacturing practices.

We provide exceptional products and quality services, ensuring that our products meet the relevant standards of various countries, and earning the trust and support of our customers.

CONTACT

103, Building 10, Lecheng Molding Industrial Park, Xinqian Street, Huangyan District, Taizhou city, Zhejiang Province