Maximizing Efficiency with Agricultural Fitting Mould: A Comprehensive Guide

2025-04-26

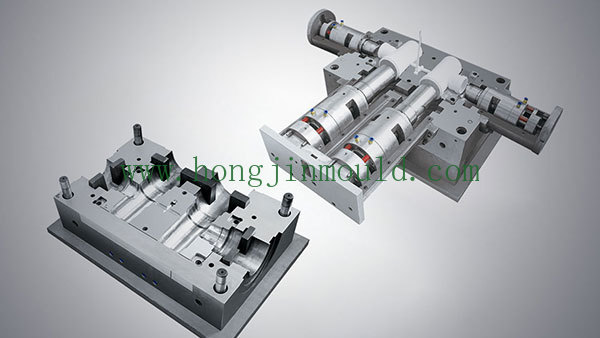

In the highly competitive landscape of manufacturing processing machinery, agricultural fitting moulds stand out as a critical component for enhancing efficiency and productivity. These moulds are specifically designed to create fittings that are essential for various agricultural equipment and machinery. Understanding the intricacies of agricultural fitting moulds is vital for manufacturers aiming to optimize their production processes.

Firstly, agricultural fitting moulds serve a fundamental role in the plastic injection molding process. They allow manufacturers to produce precise and consistent fittings that meet the rigorous demands of the agricultural industry. High-quality moulds are crafted with advanced technology to ensure durability and performance, enabling the creation of fittings that can withstand harsh operating conditions often found in agricultural settings.

The design of agricultural fitting moulds is crucial for ensuring compatibility with a wide range of agricultural machinery. Moulds can be tailored to create specific shapes and sizes of fittings, which enhances their adaptability across various equipment types. This customization not only improves the functionality of the machinery but also reduces the risk of breakdowns, which can be costly for farmers and agricultural businesses.

Moreover, utilizing well-designed agricultural fitting moulds can significantly reduce production cycle times. Efficient mould designs facilitate quicker cooling and ejection processes, minimizing the time required to produce each fitting. This efficiency translates to higher output rates, allowing manufacturers to meet growing demand in the agricultural sector without compromising on quality.

Additionally, the choice of materials used in crafting agricultural fitting moulds plays a significant role in their performance and longevity. Manufacturers often opt for high-grade steel or other durable materials that can withstand the stresses of repeated use. This consideration not only enhances the lifespan of the moulds but also contributes to the overall quality of the fittings produced.

Another significant aspect is the maintenance of agricultural fitting moulds. Regular upkeep ensures that the moulds remain in optimal condition, preventing any potential issues that could arise from wear and tear. Implementing a maintenance schedule can lead to increased productivity and fewer delays in the manufacturing process.

In conclusion, agricultural fitting moulds are indispensable in the manufacturing and processing machinery sector. Their design, material selection, and maintenance strategies directly impact production efficiency and product quality. By understanding and leveraging these elements, manufacturers can enhance their operations and better serve the agricultural industry. Investing in high-quality agricultural fitting moulds is not just about immediate returns; it is a strategic move towards long-term success and reliability in agricultural equipment manufacturing.

Firstly, agricultural fitting moulds serve a fundamental role in the plastic injection molding process. They allow manufacturers to produce precise and consistent fittings that meet the rigorous demands of the agricultural industry. High-quality moulds are crafted with advanced technology to ensure durability and performance, enabling the creation of fittings that can withstand harsh operating conditions often found in agricultural settings.

The design of agricultural fitting moulds is crucial for ensuring compatibility with a wide range of agricultural machinery. Moulds can be tailored to create specific shapes and sizes of fittings, which enhances their adaptability across various equipment types. This customization not only improves the functionality of the machinery but also reduces the risk of breakdowns, which can be costly for farmers and agricultural businesses.

Moreover, utilizing well-designed agricultural fitting moulds can significantly reduce production cycle times. Efficient mould designs facilitate quicker cooling and ejection processes, minimizing the time required to produce each fitting. This efficiency translates to higher output rates, allowing manufacturers to meet growing demand in the agricultural sector without compromising on quality.

Additionally, the choice of materials used in crafting agricultural fitting moulds plays a significant role in their performance and longevity. Manufacturers often opt for high-grade steel or other durable materials that can withstand the stresses of repeated use. This consideration not only enhances the lifespan of the moulds but also contributes to the overall quality of the fittings produced.

Another significant aspect is the maintenance of agricultural fitting moulds. Regular upkeep ensures that the moulds remain in optimal condition, preventing any potential issues that could arise from wear and tear. Implementing a maintenance schedule can lead to increased productivity and fewer delays in the manufacturing process.

In conclusion, agricultural fitting moulds are indispensable in the manufacturing and processing machinery sector. Their design, material selection, and maintenance strategies directly impact production efficiency and product quality. By understanding and leveraging these elements, manufacturers can enhance their operations and better serve the agricultural industry. Investing in high-quality agricultural fitting moulds is not just about immediate returns; it is a strategic move towards long-term success and reliability in agricultural equipment manufacturing.

We provide exceptional products and quality services, ensuring that our products meet the relevant standards of various countries, and earning the trust and support of our customers.

CONTACT

103, Building 10, Lecheng Molding Industrial Park, Xinqian Street, Huangyan District, Taizhou city, Zhejiang Province