Exploring the Role of Electrical Conduit Fitting Moulds in Smart Manufacturing

2025-04-21

Exploring the Role of Electrical Conduit Fitting Moulds in Smart Manufacturing

Table of Contents

- 1. Introduction to Electrical Conduit Fitting Moulds

- 2. The Importance of Moulds in Manufacturing

- 3. What is Smart Manufacturing?

- 4. The Role of Electrical Conduit Fitting Moulds

- 5. Materials Used in Electrical Conduit Fitting Moulds

- 6. Automation and Its Impact on Mould Production

- 7. Sustainable Practices in Mould Manufacturing

- 8. Future Trends in Electrical Conduit Fitting Moulds and Smart Manufacturing

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Electrical Conduit Fitting Moulds

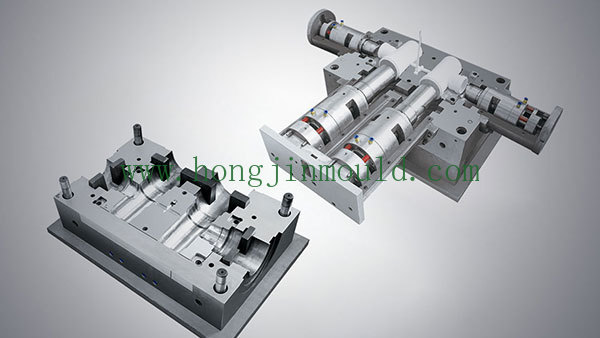

Electrical conduit fitting moulds are crucial components in the manufacturing of electrical fittings. These moulds dictate the shape, size, and functionality of the conduits that protect electrical wiring in various applications. With the rise of smart manufacturing, the role of these moulds has evolved, presenting new challenges and opportunities for manufacturers. Understanding their significance is key to optimizing production processes and ensuring product quality.

2. The Importance of Moulds in Manufacturing

Moulds serve as the backbone of many manufacturing processes, particularly in industries like plastics, metals, and ceramics. They allow manufacturers to produce consistent and precise parts at scale, which is essential in today’s competitive landscape. The **importance of moulds** extends beyond mere production; they also affect product performance, durability, and market readiness.

2.1 Enhancing Production Efficiency

Using high-quality moulds can significantly enhance production efficiency. They reduce the time it takes to set up and switch between production runs, allowing for greater flexibility and responsiveness to market demands.

2.2 Ensuring Quality Control

Quality control is critical in manufacturing, and moulds play a crucial role in this process. Precision-engineered moulds ensure that each component produced meets the required specifications and standards.

3. What is Smart Manufacturing?

Smart manufacturing refers to the integration of advanced technologies and data analytics in the production process. This includes the use of Internet of Things (IoT) devices, artificial intelligence (AI), and machine learning to create more efficient and adaptable manufacturing systems. The goal is to enhance productivity, reduce costs, and improve product quality through automation and real-time data analysis.

3.1 Key Components of Smart Manufacturing

- **IoT Devices**: These sensors and devices collect data from machines and processes to optimize operations.

- **AI and Machine Learning**: These technologies analyze data to predict maintenance needs and optimize production schedules.

- **Automation**: Automated systems reduce human error and increase efficiency, allowing for faster production cycles.

4. The Role of Electrical Conduit Fitting Moulds

Electrical conduit fitting moulds play an integral role in facilitating the transition to smart manufacturing. They must be designed to accommodate advanced materials and manufacturing techniques. Additionally, as production processes become more automated, the moulds themselves require innovative features to enhance their compatibility with technology.

4.1 Customization and Flexibility

In smart manufacturing, the ability to customize moulds for specific applications is vital. This allows manufacturers to respond swiftly to changing market needs and produce specialized products without significant downtime. Moulds designed for versatility can enhance the overall agility of the manufacturing process.

4.2 Data Integration

Integrating data collection mechanisms into mould designs can provide valuable insights into production efficiency. By monitoring performance in real time, manufacturers can identify potential issues before they escalate, leading to reduced waste and lower costs.

5. Materials Used in Electrical Conduit Fitting Moulds

The selection of materials for electrical conduit fitting moulds is crucial for ensuring durability, performance, and cost-effectiveness. Common materials include:

5.1 Steel

Steel moulds are favored for their strength and longevity. They can withstand high temperatures and pressures, making them ideal for high-volume production runs.

5.2 Aluminum

Aluminum is lightweight and offers excellent thermal conductivity. It is often used for moulds where weight and heat management are critical factors.

5.3 Thermoplastics

Thermoplastic moulds are used for their flexibility and ease of shaping. They are particularly useful in producing complex geometries in electrical conduit fittings.

6. Automation and Its Impact on Mould Production

The rise of automation in manufacturing has transformed how moulds are produced and utilized. Automated systems streamline the production process, reducing lead times and enhancing precision.

6.1 CNC Machining

Computer Numerical Control (CNC) machining has revolutionized mould production by providing unparalleled precision. CNC machines can produce intricate designs that would be almost impossible to achieve manually.

6.2 3D Printing in Mould Creation

3D printing technology allows for the rapid prototyping of moulds. This can significantly reduce the time required to bring a new product to market, enabling manufacturers to stay competitive.

7. Sustainable Practices in Mould Manufacturing

Sustainability is a growing concern in manufacturing. The production of electrical conduit fitting moulds can adopt eco-friendly practices to reduce environmental impact.

7.1 Material Recycling

Using recycled materials in mould production can significantly lower carbon footprints. Manufacturers are increasingly sourcing materials from sustainable sources or reusing materials from previous projects.

7.2 Energy Efficiency

Investing in energy-efficient machinery and practices can lead to substantial cost savings and environmental benefits. Automating processes can reduce energy consumption while maintaining productivity.

8. Future Trends in Electrical Conduit Fitting Moulds and Smart Manufacturing

Looking ahead, several trends are shaping the future of electrical conduit fitting moulds in the context of smart manufacturing.

8.1 Increased Use of Smart Materials

Smart materials that adapt to environmental conditions are likely to gain traction. These materials can enhance the functionality and longevity of electrical conduit fittings.

8.2 Enhanced Collaboration Between Humans and Machines

The future will likely see greater collaboration between human operators and automated systems. The integration of AI can lead to more intelligent decision-making processes on the shop floor.

9. Frequently Asked Questions

Q1: What are electrical conduit fitting moulds?

A1: Electrical conduit fitting moulds are specialized tools used to shape and form electrical conduits, which protect wiring and facilitate electrical installations.

Q2: How do smart manufacturing techniques improve mould production?

A2: Smart manufacturing techniques enhance mould production by integrating automation, data analytics, and IoT technologies, improving efficiency, precision, and responsiveness to market needs.

Q3: What materials are best for producing electrical conduit fitting moulds?

A3: The best materials for electrical conduit fitting moulds include steel for its strength, aluminum for its lightweight properties, and thermoplastics for flexibility.

Q4: What role does automation play in mould manufacturing?

A4: Automation streamlines mould manufacturing processes, reducing lead times, enhancing precision, and improving overall production efficiency.

Q5: How can manufacturers adopt sustainable practices in mould production?

A5: Manufacturers can adopt sustainable practices by sourcing recycled materials, investing in energy-efficient technologies, and implementing waste-reduction strategies.

10. Conclusion

In conclusion, **electrical conduit fitting moulds** are indispensable in the landscape of smart manufacturing. They not only facilitate the production of high-quality electrical fittings but also embody the advancements in technology and sustainability. As the industry continues to evolve, embracing innovations in materials, automation, and sustainable practices will be essential for staying competitive. Manufacturers who recognize the pivotal role of these moulds will be well-positioned to thrive in the future of smart manufacturing.

We provide exceptional products and quality services, ensuring that our products meet the relevant standards of various countries, and earning the trust and support of our customers.

CONTACT

103, Building 10, Lecheng Molding Industrial Park, Xinqian Street, Huangyan District, Taizhou city, Zhejiang Province