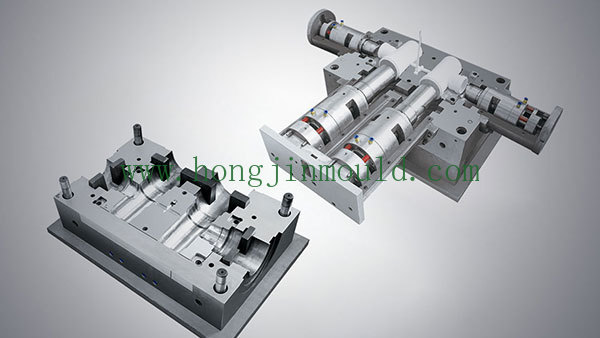

The main difficulty in achieving high precision with external thread direct molds

Specialize in manufacturing all moulds of pipe fitting series: pvc drainage pipe fitting mould, ppr cold and hot water pipe fitting mould, PE pipe fitting mould...

Keywords:

Plasticpipe fittings moulds

Category:

Hotline:

The main difficulty in achieving high precision with external thread direct molds

Detail

The main difficulty in achieving high precision with external thread direct molds

Complex geometric shapes and strict tolerances:

Tooth profile accuracy: The thread profile (such as tooth profile angle, tooth top/tooth bottom arc radius, pitch, tooth height) must be accurately replicated onto the mold cavity. Any small deviation, such as a slight deviation in angle or a slight deviation in arc radius, can lead to poor thread fit, decreased strength, or difficulty in assembly.

Cumulative pitch error: Along the length direction of the thread, small errors in each pitch will accumulate, resulting in the total length or engagement length of the thread exceeding the tolerance. Controlling the precision of individual pitch and the overall cumulative error is the key to high-precision molds.

Medium diameter accuracy: The thread medium diameter is the core dimension that determines the fitting properties, and its accuracy requirements are extremely high. It is very difficult to accurately control the pitch diameter of the formed thread on the mold, which is affected by multiple factors such as material shrinkage and mold deformation.

Lead/helix accuracy: For multi line threads or threads that require precise mating positions, the accuracy of lead and helix is crucial. The mold cavity must perfectly reproduce the required helix angle.

Classification surface and flash edge:

Location of parting line: The mold usually needs to be parting before demolding. Designing the parting surface on the thread crest (rather than the flank) is an ideal choice, but it is difficult to implement. If the parting surface passes through the tooth side, it will cause obvious parting lines and form a flying edge.

Flying edge control: Even if the parting surface is designed at the tooth crest, extremely small mold fit gaps or wear will form thin flying edges that are difficult to remove at the tooth crest. These flying edges will seriously affect the thread's fit and sealing performance. High precision molds require machining of the parting surface, extremely high fitting accuracy, and long-term stability.

Precision of mold closure: The moving and fixed molds must be precisely aligned and closed, and any slight misalignment can cause the thread profile to twist or form steps.

Difficulty of demolding and risk of damage:

Tightening force: After cooling and shrinking, plastic/metal will tightly wrap around the protruding threaded core (for internal threads) or shrink in the threaded cavity (for external threads). The friction generated during demolding is very high.

Thread damage: Forced demolding (especially for brittle materials or fine thread threads) can easily cause scratches, deformation, and even fracture of the thread teeth. High precision threads cannot withstand such damage.

The challenge of the solution: The use of sliders, threaded cores for rotating demolding (such as gear motor drive), or petal mold structures are common solutions, but these structures themselves increase the complexity and cost of the mold, and introduce additional requirements for fitting accuracy and potential wear points, affecting overall accuracy and lifespan.

Material shrinkage and deformation:

Uneven shrinkage: Both plastic and metal shrink during the cooling process. Due to its complex geometric shape and often uneven wall thickness, the shrinkage of threaded areas is often uneven and difficult to accurately predict.

Deformation: Factors such as demolding force, residual stress, and uneven mold temperature can all cause slight deformation of the formed thread, deviating from the theoretical shape of the mold cavity.

Prediction and control: Accurately predicting the shrinkage behavior of materials under specific thread geometries and compensating (scaling) during mold design is the core difficulty of high-precision mold design. This requires profound material knowledge and experience, and relies on precise CAE analysis.

The limit of mold manufacturing process:

High precision machining: It is extremely challenging to machine high-precision threaded cavities or cores on mold steel. We require ultra precision machining equipment (such as precision grinders, slow wire cutting, mirror EDM) and skilled operators.

Electrode manufacturing and wear: For threaded cavities in electrical discharge machining (EDM), it is already difficult to manufacture high-precision copper electrodes. The electrode loss during the processing directly affects the accuracy of the cavity, requiring complex compensation calculations.

Heat treatment deformation: The mold will deform during quenching and other heat treatment processes. To ensure that the critical parts of the thread can still meet the micrometer level tolerance requirements after heat treatment, special process control and subsequent precision machining are required.

Surface treatment and polishing: The threaded surface requires extremely low roughness to facilitate demolding and ensure the quality of the threaded surface. It is very difficult to polish uniformly and without changing the geometric shape on complex thread profiles.

Wear and tear and lifespan:

High wear area: The thread crest and flank experience significant friction and pressure during demolding, making them one of the fastest worn areas in the mold.

Precision attenuation: With the increase of production batches, mold wear will gradually cause changes in thread size (such as larger pitch diameter and blunted tooth profile), resulting in a decrease in precision. High precision molds require the use of high wear-resistant materials (such as hard alloys, powder metallurgy steel) and surface strengthening treatments (such as nitriding, PVD coatings).

Maintenance difficulty: Repairing worn high-precision threaded cavities is extremely difficult and costly, often better than replacing them.

Detection and verification:

Measurement difficulty: It is very difficult to accurately measure the complex thread geometric parameters inside the mold cavity, especially the pitch diameter, profile angle, and root arc. High precision specialized measuring tools are required (such as profilometers, optical projectors, high-precision coordinate measuring machines CMM with special measuring needles or scanning heads).

First article confirmation and process control: The first product formed needs to undergo comprehensive and strict thread testing (such as pass stop gauges, thread micrometers, optical measurements, airtightness tests, etc.) to indirectly verify the accuracy of the mold and establish a process control system. This itself is time-consuming and costly.

Previous

Previous

Difficulty in Precision Control of Sixteen Thread Cap

RELATED MOULDS

The main difficulty in achieving high precision with external thread direct molds

The main difficulty in achieving high precision with external thread direct molds

Difficulty in Precision Control of Sixteen Thread Cap

The main reason for the difficulty in demolding caused by spherical molds

The main reason for the difficulty in demolding caused by spherical molds

MESSAGES

We provide exceptional products and quality services, ensuring that our products meet the relevant standards of various countries, and earning the trust and support of our customers.

CONTACT

103, Building 10, Lecheng Molding Industrial Park, Xinqian Street, Huangyan District, Taizhou city, Zhejiang Province