Difficulty in Precision Control of Sixteen Thread Cap

Specialize in manufacturing all moulds of pipe fitting series: pvc drainage pipe fitting mould, ppr cold and hot water pipe fitting mould, PE pipe fitting mould...

Keywords:

Plasticpipe fittings moulds

Category:

Hotline:

Difficulty in Precision Control of Sixteen Thread Cap

Detail

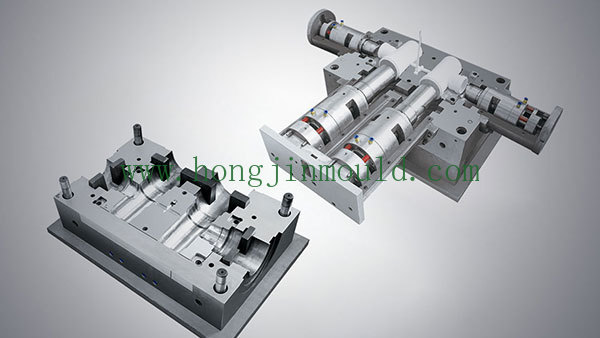

The difficulty of multi cavity molds lies in achieving similar thermal equilibrium and mechanical environment for each cavity. Therefore, the design of the mold flow channel must ensure that the inlet pressure of each cavity is consistent. However, in actual production, the temperature at the front end of the melt will decay; The threaded part usually requires a slider mechanism, and the synchronization of the actions of sixteen sets of sliders is a big challenge; In addition, the thermal expansion coefficient of the mold will be very obvious on templates with a height of 1.2 meters or more, and the temperature difference between the four corners and the middle may exceed 15 ℃.

The following are the main difficulties

Difficulty of mold flow balance (filling uniformity) doubles:

Differences in melt flow paths: Molten plastic enters the diversion channel from the main channel and is redistributed to 16 cavities. The difference in the length of the melt flow path and the bending angle between the cavities near and far from the sprue is significant.

Flow end effect: The final filled cavity has a lower melt temperature and greater pressure decay, resulting in a different shrinkage rate compared to other cavities.

Consequence: The weight, density, and shrinkage rate of threaded caps with different cavities are inconsistent. This directly leads to:

Thread size deviation: Key dimensions such as pitch, pitch diameter, and tooth profile angle fluctuate between 16 cavities, exceeding the tolerance range.

Ellipticity issue: Uneven filling and holding pressure can cause the lid to be non-circular (ovality exceeding the standard), affecting sealing and screwing.

Flying edge/shortage of material: Unbalanced flow may cause some cavities to be over pressurized (flying edge) and some to be under pressurized (shortage of material, incomplete threads).

Controlling cooling uniformity is extremely difficult:

Uneven heat distribution: There are natural differences in temperature fields between the center and edge areas of the mold. 16 cavities are densely arranged, and the design space of the cooling water circuit is limited, making it difficult to ensure that the water circuit layout and cooling efficiency around each cavity are completely consistent.

Difference in cooling rate: Uneven cooling results in different curing rates of plastic in different cavities. The areas with slow cooling experience greater shrinkage and more significant size changes.

Consequence: It exacerbated the shrinkage differences caused by the imbalance of the mold flow, resulting in inconsistent thread dimensions and overall cover dimensions (such as height and outer diameter) among the 16 cavities. Thermal deformation can also affect thread accuracy.

The precision requirements for mold manufacturing are strict:

Precision of cavity/core replication: Manufacturing 16 identical threaded cavities and cores (usually requiring complex sliders or thread demolding mechanisms) inherently imposes extreme requirements on processing equipment (such as precision CNC, slow wire, mirror spark machines), cutting tools, clamping, and measurement techniques. Any small machining error (a few micrometers) will be replicated on 16 products.

Synchronization and accuracy of slider mechanism: Threads are usually formed by sliders. The opening and closing actions of the 16 sets of sliders must be highly synchronized and run smoothly without any jamming, otherwise it will cause:

Thread misalignment (such as burrs and steps at the parting surface).

Uneven wear of the slider affects its lifespan and long-term accuracy.

Uneven ejection leads to product deformation.

Rigid deformation of mold: Under enormous injection pressure (tens to hundreds of tons), the mold template will undergo elastic deformation. For large multi cavity molds (usually with larger mold sizes), this deformation is different at the center and edges of the mold, resulting in the actual size of the cavity not being completely consistent under pressure.

Anisotropy and fluctuation of material shrinkage:

Plastic materials, especially crystalline materials such as PP and PE, have different shrinkage rates in the flow direction and vertical direction. In complex multi cavity flow, the performance of this anisotropy in each cavity is difficult to fully predict and control.

The small fluctuations between batches of raw materials themselves can be amplified in multi cavity molds, affecting the consistency between products from different batches.

Top out system balance:

It is crucial to ensure that all 16 products are ejected simultaneously, smoothly, and evenly under stress. Uneven ejection can cause deformation of the product during ejection, especially for thin-walled and fine structures such as threads.

Previous

The main reason for the difficulty in demolding caused by spherical molds

RELATED MOULDS

Difficulty in Precision Control of Sixteen Thread Cap

The main reason for the difficulty in demolding caused by spherical molds

The main reason for the difficulty in demolding caused by spherical molds

MESSAGES

We provide exceptional products and quality services, ensuring that our products meet the relevant standards of various countries, and earning the trust and support of our customers.

CONTACT

103, Building 10, Lecheng Molding Industrial Park, Xinqian Street, Huangyan District, Taizhou city, Zhejiang Province