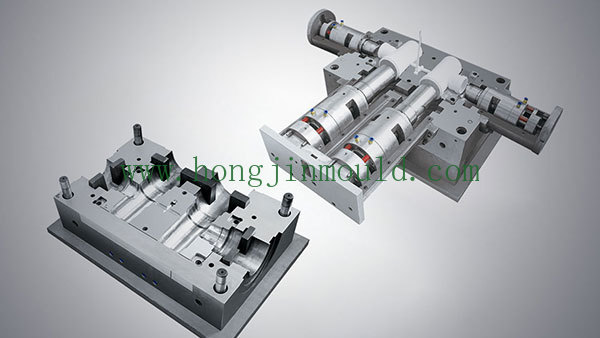

CPVC reduced diameter elbow mold

Specialize in manufacturing all moulds of pipe fitting series: pvc drainage pipe fitting mould, ppr cold and hot water pipe fitting mould, PE pipe fitting mould...

Keywords:

Plasticpipe fittings moulds

Category:

Hotline:

CPVC reduced diameter elbow mold

Detail

1. Basic structure of mold

Mold cavity design: Accurately machined according to the angle of the elbow (such as 45 °, 90 °) and the reduction ratio (such as DN50 → DN32) to ensure a smooth transition of the flow channel.

Shrinkage section: Adopting a conical or stepped design, gradually reducing the diameter to avoid fluid turbulence.

Splitting line: It is usually a two half mold structure, which is easy to demold. The parting surface needs high-precision processing to prevent burrs.

2. Material selection

Mold steel: commonly used pre hardened or heat-treated steels such as P20 and H13, which are corrosion-resistant and wear-resistant.

Surface treatment: chrome plating or nitriding treatment to improve surface hardness and extend mold life.

3. Production process

Injection molding: CPVC pellets are melted at 180-220 ℃ and injected into the mold, requiring precise temperature control to prevent decomposition.

Cooling system: Built in waterway for rapid cooling, shortening the cycle time (usually 20-60 seconds).

Demoulding mechanism: ejector pin or pneumatic demoulding to avoid deformation.

4. Key parameters

Shrinkage ratio: generally not exceeding 50% (such as DN40 → DN25), to avoid sharp changes that may cause a decrease in strength.

Bending radius: typically 1.5 times the pipe diameter (R=1.5D), in compliance with ANSI/ASME standards.

Wall thickness control: The mold needs to ensure that the minimum wall thickness after diameter reduction is ≥ the standard value (such as SCH80).

5. Quality control

Dimensional inspection: Verify the reduced diameter section and bending angle using calipers and projectors.

Pressure test: The finished product needs to pass a water pressure test (such as 1.5 times the working pressure).

Material certification: Complies with ASTM F441 standard (CPVC fittings).

Previous

Previous

PPR material characteristics and process parameters

RELATED MOULDS

PPR material characteristics and process parameters

Market demand trend of environmentally friendly PPR hot and cold water pipes

Market demand trend of environmentally friendly PPR hot and cold water pipes

Characteristics of environmentally friendly PPR hot and cold water pipes

Characteristics of environmentally friendly PPR hot and cold water pipes

MESSAGES

We provide exceptional products and quality services, ensuring that our products meet the relevant standards of various countries, and earning the trust and support of our customers.

CONTACT

103, Building 10, Lecheng Molding Industrial Park, Xinqian Street, Huangyan District, Taizhou city, Zhejiang Province