A Closer Look at the Materials Used in Plastic Pipe Fittings Moulds

2025-08-18

A Closer Look at the Materials Used in Plastic Pipe Fittings Moulds

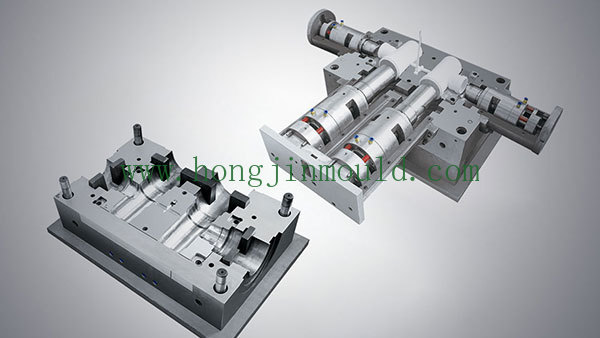

Introduction to Plastic Pipe Fittings Moulds

Plastic pipe fittings are integral components in various industries, including plumbing, construction, and automotive manufacturing. They facilitate the efficient flow of liquids and gases, ensuring robust connections and lasting durability. At the heart of producing these fittings lies the mould, which shapes the raw materials into the desired forms. Understanding the materials used in these moulds is crucial for manufacturers aiming to enhance product quality and optimize production processes.

Why Material Selection Matters in Mould Manufacturing

The choice of materials for mould manufacturing directly impacts the final product's quality, durability, and cost-effectiveness. Different materials come with unique properties that can either enhance or hinder production efficiency. A well-informed approach to material selection can lead to improved cycle times, reduced maintenance costs, and superior product performance.

Key Factors Influencing Material Choice

When selecting materials for plastic pipe fittings moulds, manufacturers must consider several factors:

1. **Thermal Conductivity**: The ability of a material to conduct heat influences cooling rates during the injection molding process.

2. **Mechanical Strength**: The mould must withstand high pressure and wear during repeated use.

3. **Corrosion Resistance**: Exposure to various chemicals necessitates materials that can resist corrosion over time.

4. **Cost Efficiency**: Balancing material costs with performance and longevity is essential for maximizing profitability.

Common Materials Used in Plastic Pipe Fittings Moulds

This section delves into the most commonly used materials in the production of plastic pipe fittings moulds, examining their properties, benefits, and applications.

1. Steel Alloys

Steel alloys are among the most popular choices for mould manufacturing due to their high durability and strength. Various steel grades offer different properties:

- **P20 Steel**: Known for its good machinability and toughness, P20 is often used for low-volume production and prototyping.

- **H13 Steel**: This grade exhibits excellent heat resistance and is ideal for high-volume production. It can withstand high temperatures and is suitable for hot runner systems.

Advantages of Steel Alloys

- **Long Lifespan**: Steel moulds can endure extensive use, making them a cost-effective choice over time.

- **Precision Machining**: Steel can be machined into intricate designs, allowing for detailed moulds that produce complex fittings.

2. Aluminum Alloys

Aluminum is another popular material for plastic pipe fittings moulds, particularly in applications requiring lightweight and corrosion-resistant properties.

- **7075 Aluminum**: This alloy is known for its high strength-to-weight ratio, making it suitable for industries where weight savings are crucial.

Benefits of Aluminum Alloys

- **Faster Production Times**: Aluminum moulds can be manufactured more quickly than steel, leading to shorter lead times in production.

- **Improved Thermal Conductivity**: Aluminum dissipates heat more efficiently, reducing cycle times and enhancing production efficiency.

3. Copper Alloys

Copper and its alloys, such as bronze, are used in specific applications due to their excellent thermal conductivity and corrosion resistance.

Applications of Copper Alloys

- **High-Temperature Moulds**: Copper moulds perform well under high-temperature conditions, making them suitable for specialized plastic formulations.

4. Composite Materials

Composite materials, such as fiberglass reinforced plastics, are increasingly used in mould manufacturing due to their unique properties.

Advantages of Composite Materials

- **Weight Savings**: Composites are typically lighter than metal alternatives, reducing transportation costs.

- **Customization**: Composite moulds can be easily tailored to specific requirements, offering flexibility in design and functionality.

Innovations in Mould Materials

The advancement of technology has seen the emergence of innovative materials designed to enhance performance and efficiency in mould manufacturing.

1. 3D-Printed Moulds

Additive manufacturing, or 3D printing, has revolutionized the way moulds can be produced. This technique allows for the creation of complex geometries that may not be feasible with traditional methods.

Benefits of 3D-Printed Moulds

- **Rapid Prototyping**: Manufacturers can quickly produce prototypes for testing, streamlining the product development process.

- **Reduced Material Waste**: Additive manufacturing minimizes waste compared to traditional subtractive methods.

2. Biodegradable Materials

As sustainability becomes increasingly important, biodegradable materials are gaining traction in the mould manufacturing industry.

Applications of Biodegradable Materials**

- **Environmental Impact**: Using biodegradable polymers in moulds can reduce plastic waste and enhance sustainability efforts.

Choosing the Right Material for Your Application

Selecting the appropriate material for plastic pipe fittings moulds requires careful consideration of the end application and production requirements.

Assessing Your Production Needs

Consider the following factors when choosing materials:

- **Volume of Production**: High-volume productions may benefit from durable materials like steel, while low-volume runs may find aluminum or composite materials more viable.

- **Type of Plastic**: The choice of plastic being molded can impact the material selection for the mould.

- **Cost Constraints**: Balancing initial material costs with long-term performance and durability is vital.

Testing and Quality Assurance

Before finalizing a material choice, conducting thorough testing is essential to ensure it meets the necessary specifications and performance criteria.

Quality Control Measures

Implementing quality control measures can help mitigate risks and ensure consistent product quality throughout the manufacturing process.

Maintenance of Moulds for Longevity

Proper maintenance of moulds is crucial for maximizing their lifespan and ensuring optimal performance.

Regular Inspections

Conducting regular inspections can help identify wear and tear, preventing costly downtimes.

Cleaning and Maintenance Tips

- **Routine Cleaning**: Regularly clean moulds to remove residue and prevent contamination.

- **Lubrication**: Ensure proper lubrication of moving parts to minimize friction and wear.

FAQs about Materials Used in Plastic Pipe Fittings Moulds

1. What are the most common materials used in plastic pipe fittings moulds?

The most common materials include steel alloys, aluminum alloys, copper alloys, and composite materials, each offering unique properties and advantages.

2. How does material choice affect production efficiency?

The right material can enhance thermal conductivity, reduce cycle times, and improve durability, all of which contribute to increased production efficiency.

3. Are 3D-printed moulds as durable as traditional moulds?

While 3D-printed moulds can be durable, their longevity compared to traditional moulds depends on the material used and the specific application.

4. Can biodegradable materials be used for high-temperature applications?

Biodegradable materials may not be suitable for high-temperature applications due to their thermal limitations, but advancements in material science may provide alternatives in the future.

5. How can I ensure the longevity of my moulds?

Regular maintenance, including cleaning and lubrication, as well as routine inspections, can significantly enhance the lifespan of your moulds.

Conclusion

The choice of materials used in plastic pipe fittings moulds plays a critical role in determining the overall quality, efficiency, and sustainability of the manufacturing process. By carefully assessing the properties and advantages of various materials, manufacturers can make informed decisions that align with their production needs and market demands. As technology continues to evolve, staying updated on innovative materials and manufacturing techniques will be essential for maintaining competitive advantage in the ever-evolving landscape of plastic mould production.

We provide exceptional products and quality services, ensuring that our products meet the relevant standards of various countries, and earning the trust and support of our customers.

CONTACT

103, Building 10, Lecheng Molding Industrial Park, Xinqian Street, Huangyan District, Taizhou city, Zhejiang Province