Exploring the Different Types of Irrigation Fitting Moulds Available Today

2025-08-09

Exploring the Different Types of Irrigation Fitting Moulds Available Today

Table of Contents

- Introduction to Irrigation Fitting Moulds

- The Importance of Irrigation in Agriculture

- Types of Irrigation Fitting Moulds

- Materials Used in Mould Manufacturing

- The Manufacturing Process of Irrigation Fitting Moulds

- Applications of Irrigation Fitting Moulds

- Choosing the Right Mould for Your Needs

- Maintenance Tips for Irrigation Fitting Moulds

- The Future of Irrigation Fitting Moulds

- Frequently Asked Questions

- Conclusion

Introduction to Irrigation Fitting Moulds

Irrigation fitting moulds play a pivotal role in modern agriculture by facilitating the efficient delivery of water to crops. These moulds are essential components used to manufacture various irrigation fittings, ensuring that water is distributed evenly and effectively. With the increasing demand for sustainable agricultural practices, understanding the types and applications of irrigation fitting moulds becomes even more critical.

The Importance of Irrigation in Agriculture

Water is the lifeblood of agriculture. Irrigation systems are vital in ensuring that crops receive adequate moisture, especially in arid regions. Efficient irrigation practices not only boost crop yields but also conserve water. As the global population grows, the need for innovative irrigation solutions increases, making irrigation fitting moulds a crucial aspect of agricultural development.

Types of Irrigation Fitting Moulds

When it comes to irrigation fitting moulds, several types are specifically designed to meet various agricultural needs. Understanding these types helps manufacturers and farmers choose the right moulds for their irrigation systems.

Inline Moulds

Inline moulds are designed for producing fittings that facilitate seamless water flow within irrigation systems. These moulds are crucial for creating connectors and pipes that are directly integrated into irrigation setups. The efficiency of inline moulds lies in their ability to produce lightweight but durable fittings that can withstand pressure over time.

Sprinkler Moulds

Sprinkler moulds are used to create various components of sprinkler irrigation systems, including sprinkler heads, risers, and connectors. They are designed to ensure that water is sprayed evenly across the field, promoting uniform crop growth. The versatility of sprinkler moulds allows for customization in terms of size and design, catering to different agricultural needs.

Drip Irrigation Moulds

Drip irrigation moulds are essential for creating fittings that support drip systems. These moulds produce drippers, hoses, and connectors that deliver water directly to the plant's roots, minimizing waste and maximizing efficiency. Drip irrigation is particularly valuable in regions where water conservation is critical, and the use of these moulds enhances the system's overall performance.

Valve Moulds

Valve moulds are responsible for manufacturing the control mechanisms that regulate water flow within irrigation systems. These fittings ensure that water is delivered precisely when and where it is needed, preventing wastage. The precision in creating valve moulds is vital, as even minor flaws can lead to significant irrigation inefficiencies.

Materials Used in Mould Manufacturing

The choice of materials for manufacturing irrigation fitting moulds significantly impacts their durability and performance. Common materials include:

- **Plastic**: Lightweight and corrosion-resistant, plastic moulds are widely used due to their cost-effectiveness and flexibility in design.

- **Metal**: Often used for more heavy-duty applications, metal moulds provide enhanced strength and durability.

- **Composite Materials**: Combining the advantages of various materials, composites offer excellent resistance to environmental factors while maintaining lightweight properties.

Understanding the different materials available helps manufacturers make informed decisions when creating irrigation fittings tailored to specific agricultural requirements.

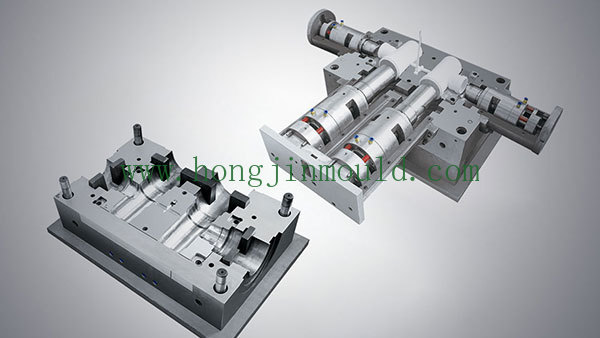

The Manufacturing Process of Irrigation Fitting Moulds

The process of manufacturing irrigation fitting moulds involves several key steps:

1. **Design and Prototyping**: The first stage involves designing the mould based on the desired specifications. CAD software is often used to create accurate prototypes.

2. **Material Selection**: Choosing the right material for the mould is crucial for ensuring its durability and effectiveness.

3. **Machining**: The selected material is machined into the desired shape, ensuring precise dimensions that meet the design specifications.

4. **Mould Assembly**: After machining, the various components of the mould are assembled to create a complete unit.

5. **Testing**: Before mass production, the mould undergoes rigorous testing to ensure it meets quality standards and performs as expected.

6. **Production**: Once testing is complete, the mould is ready for mass production, allowing manufacturers to create irrigation fittings in large quantities efficiently.

This manufacturing process emphasizes the need for quality control and precision to ensure that the final products meet agricultural demands.

Applications of Irrigation Fitting Moulds

Irrigation fitting moulds are used across various applications, including:

- **Agricultural Fields**: Ensuring efficient water distribution for crops, leading to improved yields.

- **Greenhouses**: Supporting controlled environments where precise irrigation is crucial for plant growth.

- **Landscaping**: Providing solutions for residential and commercial landscaping projects that require effective water management.

- **Industrial Applications**: Used in larger-scale operations where water delivery systems are necessary for production processes.

The versatility of irrigation fitting moulds makes them essential in various sectors beyond traditional agriculture.

Choosing the Right Mould for Your Needs

Selecting the appropriate irrigation fitting mould involves considering several factors:

- **Application Requirements**: Understanding the specific needs of your irrigation system ensures you choose a mould that meets those requirements.

- **Material Durability**: Consider the environmental conditions the mould will face, including exposure to UV rays and corrosive elements.

- **Design Flexibility**: Choose moulds that allow for customization to cater to unique irrigation challenges.

- **Cost-Effectiveness**: Balance quality and cost when selecting moulds to ensure a good return on investment.

By considering these factors, manufacturers and users alike can make informed choices that enhance irrigation efficiency.

Maintenance Tips for Irrigation Fitting Moulds

Proper maintenance of irrigation fitting moulds is essential for ensuring their longevity and performance. Here are some tips:

- **Regular Inspection**: Periodically check for signs of wear or damage to avoid unexpected failures.

- **Cleaning**: Keep moulds clean to prevent blockages and ensure smooth operation.

- **Proper Storage**: Store moulds in a dry, cool place to prevent deterioration from environmental factors.

- **Lubrication**: Apply lubricants to moving parts to ensure smooth operation and reduce friction.

Regular maintenance practices can significantly extend the lifespan of irrigation fitting moulds and improve their efficiency.

The Future of Irrigation Fitting Moulds

As agricultural practices evolve, the future of irrigation fitting moulds looks promising. Innovations in materials and manufacturing techniques are paving the way for more efficient and sustainable irrigation solutions. The integration of smart technology, such as sensors and automation, is expected to enhance the functionality of irrigation systems, making the role of moulds even more critical.

Moreover, the focus on sustainability and water conservation in agriculture is driving the demand for advanced irrigation technologies, suggesting a bright future for the mould manufacturing industry.

Frequently Asked Questions

What are irrigation fitting moulds?

Irrigation fitting moulds are tools used to manufacture various fittings and components for irrigation systems, ensuring the effective delivery of water to crops.

What materials are commonly used for manufacturing these moulds?

Common materials include plastic, metal, and composite materials, each offering different advantages depending on the application.

How can I choose the right mould for my irrigation system?

Consider factors such as application requirements, material durability, design flexibility, and cost-effectiveness when selecting a mould.

What maintenance practices can extend the lifespan of irrigation fitting moulds?

Regular inspection, cleaning, proper storage, and lubrication are key maintenance practices that help prolong the lifespan of these moulds.

What is the role of technology in the future of irrigation fitting moulds?

Innovations in materials and smart technology are expected to enhance irrigation efficiency and functionality, making moulds even more essential in modern agriculture.

Conclusion

Irrigation fitting moulds are indispensable components of modern agricultural practices, facilitating efficient water distribution to crops. Understanding the various types of moulds, their applications, and maintenance is crucial for both manufacturers and farmers. As technology continues to evolve, the future of irrigation fitting moulds promises exciting developments that will further enhance agricultural efficiency and sustainability. Embracing these innovations will not only improve crop yields but also contribute to a more sustainable approach to water management in agriculture.

We provide exceptional products and quality services, ensuring that our products meet the relevant standards of various countries, and earning the trust and support of our customers.

CONTACT

103, Building 10, Lecheng Molding Industrial Park, Xinqian Street, Huangyan District, Taizhou city, Zhejiang Province