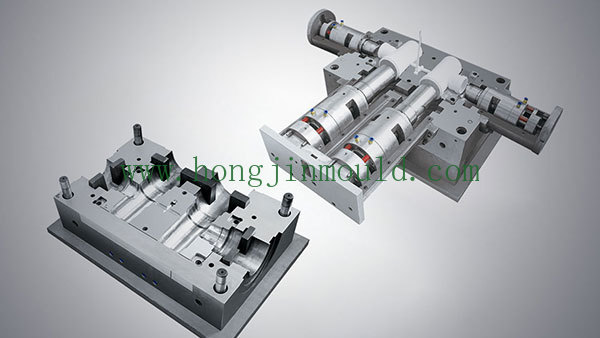

Essential Insights into Plastic Valve Moulds for Efficient Manufacturing

2025-08-14

Plastic valve moulds are essential tools in the production of various plastic components used in an array of industries, including automotive, aerospace, and plumbing. The design and fabrication of these moulds require a thorough understanding of material properties, manufacturing techniques, and the operational functions of the valves they produce.

Firstly, the design of plastic valve moulds typically involves computer-aided design (CAD) software, which allows engineers to create precise and intricate mould designs that can accommodate the specific requirements of different valve types. The choice of materials for mould construction, such as steel or aluminum, is also critical, as it impacts the durability and performance of the mould during the injection moulding process.

The manufacturing process of plastic valve moulds generally involves several key steps: machining, assembly, and testing. Machining entails cutting and shaping the material to create the mould components, which must then be assembled carefully to ensure proper alignment and functionality. Rigorous testing follows, where prototypes of the valves are produced to evaluate the mould's accuracy and efficiency. Each step in the process is vital to ensure that the final product meets industry standards and client specifications.

One of the primary benefits of investing in high-quality plastic valve moulds is the potential for increased production efficiency. Well-designed moulds can lead to faster cycle times and reduced waste, contributing to lower overall production costs. Additionally, precision moulds minimize the risk of defects in the final products, which is particularly crucial when producing components that require high reliability, such as those used in safety-critical applications.

Another advantage is the adaptability of plastic valve moulds. They can be designed to accommodate various plastic materials, including thermoplastics and thermosetting plastics, allowing manufacturers to cater to a diverse range of applications. This versatility can be a significant asset in a competitive market where the ability to swiftly adapt to changing customer demands is paramount.

In conclusion, understanding the complexities of plastic valve moulds is essential for professionals in the manufacturing and machining industry. From the initial design phase through to the final testing, each stage of the mould production process significantly influences the overall quality and efficiency of plastic component manufacturing. By focusing on these aspects, manufacturers can ensure their products meet market demands while optimizing production processes.

Firstly, the design of plastic valve moulds typically involves computer-aided design (CAD) software, which allows engineers to create precise and intricate mould designs that can accommodate the specific requirements of different valve types. The choice of materials for mould construction, such as steel or aluminum, is also critical, as it impacts the durability and performance of the mould during the injection moulding process.

The manufacturing process of plastic valve moulds generally involves several key steps: machining, assembly, and testing. Machining entails cutting and shaping the material to create the mould components, which must then be assembled carefully to ensure proper alignment and functionality. Rigorous testing follows, where prototypes of the valves are produced to evaluate the mould's accuracy and efficiency. Each step in the process is vital to ensure that the final product meets industry standards and client specifications.

One of the primary benefits of investing in high-quality plastic valve moulds is the potential for increased production efficiency. Well-designed moulds can lead to faster cycle times and reduced waste, contributing to lower overall production costs. Additionally, precision moulds minimize the risk of defects in the final products, which is particularly crucial when producing components that require high reliability, such as those used in safety-critical applications.

Another advantage is the adaptability of plastic valve moulds. They can be designed to accommodate various plastic materials, including thermoplastics and thermosetting plastics, allowing manufacturers to cater to a diverse range of applications. This versatility can be a significant asset in a competitive market where the ability to swiftly adapt to changing customer demands is paramount.

In conclusion, understanding the complexities of plastic valve moulds is essential for professionals in the manufacturing and machining industry. From the initial design phase through to the final testing, each stage of the mould production process significantly influences the overall quality and efficiency of plastic component manufacturing. By focusing on these aspects, manufacturers can ensure their products meet market demands while optimizing production processes.

We provide exceptional products and quality services, ensuring that our products meet the relevant standards of various countries, and earning the trust and support of our customers.

CONTACT

103, Building 10, Lecheng Molding Industrial Park, Xinqian Street, Huangyan District, Taizhou city, Zhejiang Province