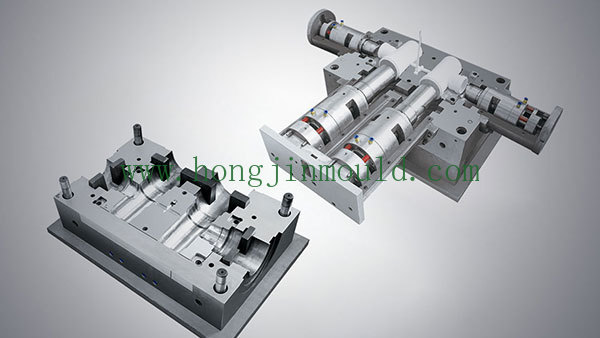

Essential Guide to Maintaining Your Plastic Pipe Fittings Mould for Longevity

2025-06-30

How to Maintain Your Plastic Pipe Fittings Mould for Longevity

Maintaining your plastic pipe fittings mould is crucial for ensuring its longevity and efficiency. Proper care can significantly reduce downtime and costs associated with replacements. In this guide, we will explore various methods and practices that can help you maintain your mould effectively.

Understanding the Importance of Mould Maintenance

Plastic pipe fittings moulds endure a rigorous manufacturing process, constantly exposed to temperature fluctuations and pressure. Regular maintenance is not just about extending the lifespan of the mould; it also ensures consistent production quality and reduces the risk of defects.

Benefits of Regular Mould Maintenance

- Increased Lifespan: Regular maintenance can double or even triple the lifespan of your mould.

- Cost Savings: Reducing the frequency of mould replacements lowers production costs.

- Improved Quality: Well-maintained moulds produce high-quality fittings with fewer defects.

- Enhanced Efficiency: A clean and well-maintained mould operates more efficiently, resulting in higher productivity.

Essential Maintenance Practices for Plastic Pipe Fittings Moulds

1. Regular Cleaning Procedures

Cleaning your mould after each production run is paramount. Residual materials can affect the quality of future productions and lead to increased wear and tear.

Cleaning Solutions

Utilize appropriate cleaning agents that are non-abrasive and compatible with the mould material. Common solutions include:

- Hot Water: For removing general residues.

- Degreasers: Useful for eliminating oily substances.

- Alcohol-based Cleaners: Effective for disinfecting and removing stubborn residues.

2. Inspection and Assessment

Regular inspections help identify wear and damage before they escalate. Key areas to inspect include:

- Surface Condition: Look for scratches, dents, or signs of wear.

- Cooling Channels: Ensure they are free of blockages to maintain optimal cooling.

- Alignment: Check for misalignments that could affect production quality.

3. Lubrication Techniques

Correct lubrication is essential to prevent friction and wear on moving parts. Use a lubricant suitable for the mould material and operating conditions.

Types of Lubricants

- Synthetic Oils: Provide excellent thermal stability and reduced friction.

- Greases: Ideal for parts that require long-lasting lubrication.

- Dry Lubricants: Useful in high-temperature applications where wet lubricants could evaporate.

4. Temperature Control

Maintaining optimal temperatures during moulding processes is vital. Too high or too low temperatures can cause warping or other defects. Utilize temperature control devices to monitor and adjust temperatures as necessary.

5. Proper Storage Practices

When not in use, store your moulds in a clean, dry environment. Protective covers can prevent dust accumulation, while climate control ensures that temperature and humidity levels remain stable.

Operational Best Practices for Extended Mould Life

1. Training Operators

Ensure that all operators are thoroughly trained on proper mould handling, cleaning, and maintenance procedures. A well-informed team can significantly reduce the likelihood of damage due to human error.

2. Monitoring Production Cycles

Keep track of production cycles to anticipate maintenance needs. Regularly updating production logs will help in scheduling inspections and cleaning.

3. Utilizing Advanced Technologies

Consider integrating advanced technologies such as automated monitoring systems that can alert operators to potential issues before they escalate.

Common Mould Issues and Their Solutions

1. Uneven Moulding

Symptoms of uneven moulding may include inconsistent wall thickness or surface quality. This can often be remedied by ensuring proper temperature control and adequate cooling.

2. Shortened Product Life

Products that fail prematurely may indicate excessive wear on the mould. Regular inspections, cleaning, and alignment checks can help address this issue.

3. Surface Defects

Surface defects such as scratches or discoloration can often be traced back to a lack of cleaning or improper handling of the mould. Implementing strict cleaning protocols can mitigate these problems.

Frequently Asked Questions (FAQs)

1. How often should I clean my plastic pipe fittings mould?

It is recommended to clean your mould after every production run to maintain optimal conditions and prevent contamination.

2. What cleaning agents are best for mould maintenance?

Non-abrasive cleaning agents such as hot water, degreasers, and alcohol-based cleaners are effective for cleaning moulds.

3. How can I prevent rust on metal mould parts?

Applying a thin layer of protective oil can help prevent rust. Additionally, store metal parts in a dry environment.

4. What are the signs of mould wear and tear?

Common signs include surface scratches, inconsistencies in product quality, and frequent production issues.

5. Can I use regular oil for lubrication?

It’s advisable to use lubricants specifically designed for mould applications to ensure compatibility and performance.

Conclusion

Maintaining your plastic pipe fittings mould is not just a task; it’s an investment in your production efficiency and product quality. By adopting regular cleaning practices, conducting thorough inspections, and training your operators, you will extend the lifespan of your moulds while reducing costs. Implement these strategies today for a more efficient and cost-effective operation tomorrow.

We provide exceptional products and quality services, ensuring that our products meet the relevant standards of various countries, and earning the trust and support of our customers.

CONTACT

103, Building 10, Lecheng Molding Industrial Park, Xinqian Street, Huangyan District, Taizhou city, Zhejiang Province