Understanding the Critical Role of Plastic Pipe Fittings Mould in Modern Manufacturing

Understanding the Critical Role of Plastic Pipe Fittings Mould in Modern Manufacturing

· 1. Introduction to Plastic Pipe Fittings Mould

· 2. Importance of Plastic Pipe Fittings in Manufacturing

· 3. The Design Process of Plastic Pipe Fittings Mould

· 4. Materials Used for Plastic Pipe Fittings Mould

· 5. Manufacturing Process of Plastic Pipe Fittings Mould

· 6. Advantages of Using Moulds for Plastic Pipe Fittings

· 7. Future Trends in Plastic Pipe Fittings Mould Technology

· 8. FAQs about Plastic Pipe Fittings Mould

· 9. Conclusion

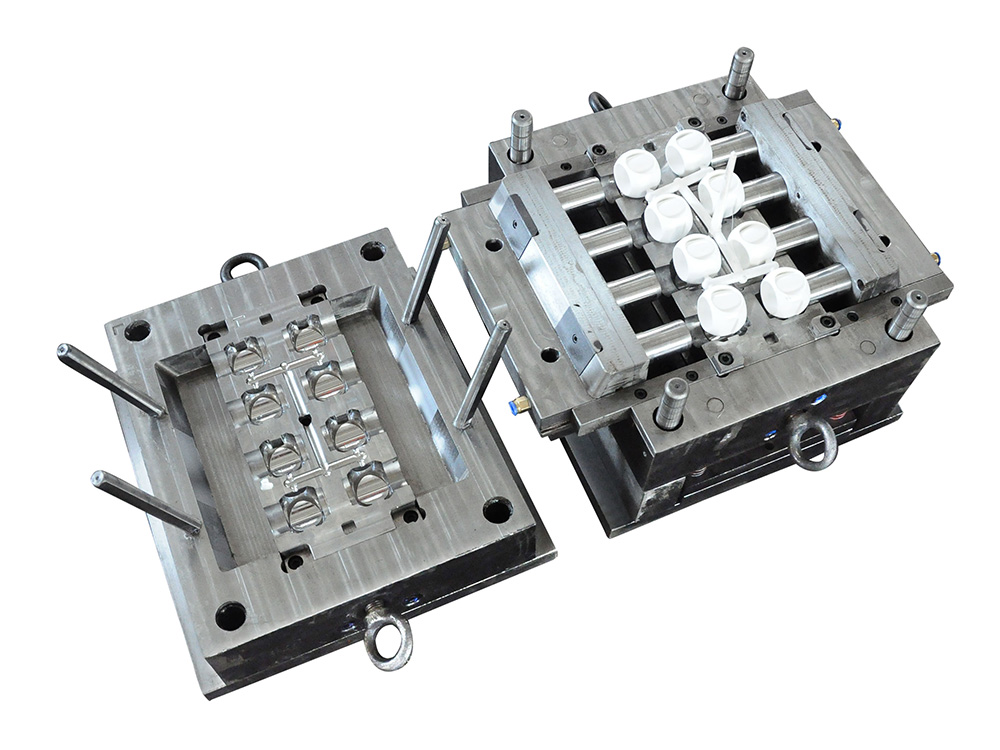

Plastic Pipe Fittings Mould

Plastic Pipe Fittings Mould

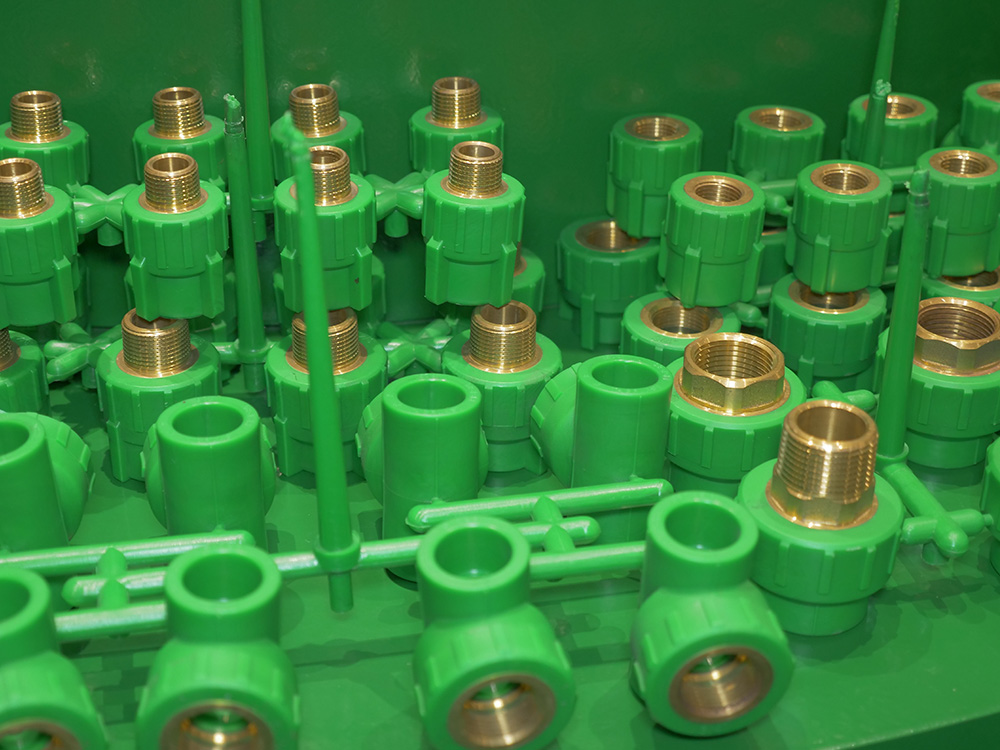

Plastic pipe fittings moulds play a crucial role in various manufacturing sectors, especially in plumbing and construction. These moulds facilitate the mass production of plastic connectors and fittings used in piping systems. With the increasing demand for durable and lightweight materials, plastic has become the preferred choice for many applications. Understanding how these moulds work and their significance can provide valuable insights into the manufacturing processes that shape our modern world.

Plastic pipe fittings are essential components in plumbing systems, HVAC, and other industrial applications. Their importance extends beyond functionality; they contribute to efficiency, safety, and sustainability in manufacturing.

Plastic fittings resist corrosion, making them ideal for various environments, including those exposed to moisture and chemicals. This durability reduces the need for frequent replacements, leading to lower maintenance costs.

Utilizing plastic pipe fittings can significantly cut down costs in manufacturing and construction projects. They are lighter than metal counterparts, which lowers shipping expenses and labor costs during installation.

Modern manufacturing increasingly emphasizes sustainability. Plastic pipe fittings can be made from recyclable materials, aligning with eco-friendly practices. This contributes to reduced waste and promotes a circular economy.

The design of plastic pipe fittings moulds is a meticulous process that requires expertise in engineering and manufacturing principles.

The process begins with an initial concept based on the desired specifications of the fittings. Using computer-aided design (CAD) software, engineers create prototypes that can be tested for functionality and performance.

Design optimization focuses on enhancing the mould's efficiency. This includes analyzing the cooling channels, gate designs, and ejection mechanisms, ensuring that the moulds yield high-quality products with minimal defects.

The choice of materials for constructing moulds significantly impacts the quality of the final product.

Steel is commonly used for its durability and ability to withstand high temperatures, making it suitable for long production runs. Aluminum, while less durable, is lighter and often preferred for smaller production runs due to its lower cost.

In recent years, composite materials have gained popularity. They offer high strength-to-weight ratios and can be tailored to specific applications, making them versatile for different moulding processes.

The manufacturing process involves several steps, which ensure that the moulds are precisely crafted to meet industry standards.

Injection moulding is the most common method for producing plastic pipe fittings. In this process, molten plastic is injected into the mould under high pressure, allowing for intricate designs and quick production cycles.

Compression moulding is another technique used, especially for thermosetting plastics. This process involves placing the plastic material into a heated mould cavity, where it is compressed and allowed to cure, forming the desired shape.

Quality control is a critical step in the manufacturing process. Rigorous testing ensures that the moulds produce fittings that meet all required specifications and standards for safety and performance.

Using moulds for plastic pipe fittings offers numerous advantages that enhance production efficiency and product quality.

Moulds ensure that each fitting is produced to exact specifications, providing a level of precision that manual manufacturing cannot achieve. This consistency is vital for maintaining the integrity of piping systems.

The use of moulds minimizes material waste during production. By optimizing the mould design and manufacturing process, companies can significantly reduce excess material usage, contributing to better sustainability practices.

The versatility of moulds allows manufacturers to produce a wide range of fittings to meet specific application needs. This flexibility is essential in adapting to market demands and technological advancements.

As technology evolves, so do the methods and materials used in plastic pipe fittings mould production.

3D printing technology is making waves in the mould manufacturing industry. It allows for rapid prototyping and customization, enabling manufacturers to create complex designs quickly and efficiently.

The integration of IoT (Internet of Things) in the manufacturing process enables real-time monitoring and data analysis. This trend helps optimize production lines and improve quality control.

The growing emphasis on sustainability is pushing manufacturers to adopt eco-friendly materials and processes. Innovations in recyclable plastics and energy-efficient manufacturing methods are on the rise.

A1: The lifespan of plastic pipe fittings can vary depending on the material and application but generally ranges from 20 to 50 years when properly installed and maintained.

A2: Yes, many plastic pipe fittings can be recycled, especially if made from thermoplastic materials. It's crucial to check local recycling regulations for specific guidance.

A3: Plastic pipe fittings are used in plumbing, irrigation, drainage systems, HVAC, and industrial applications due to their versatility and resistance to corrosion.

A4: Consider factors like the type of application, pressure ratings, temperature resistance, and compatibility with other materials when selecting plastic pipe fittings.

A5: Plastic pipe fittings are often lighter, reducing transportation emissions, and many are made from recyclable materials, supporting sustainable practices.

Plastic pipe fittings moulds are integral to modern manufacturing, providing efficiency, durability, and sustainability. As industries evolve, the importance of these moulds will only grow, driven by technological advances and a commitment to environmental responsibility. Understanding their role not only aids in appreciating the manufacturing process but also highlights the innovations that continue to shape our world. Embracing these advancements promises a future where manufacturing is more efficient, cost-effective, and sustainable, ensuring that industries can meet the demands of an ever-changing market.

This website uses cookies to ensure you get the best experience on our website.

Comment

(0)