Understanding Plastic Pipe Fittings Mould: A Comprehensive Guide

Plastic pipe fittings mould play a crucial role in the manufacturing of plastic pipe fittings, which are essential components in various industries, including plumbing, construction, and irrigation. The process of creating these moulds is intricate, combining advanced technology and skilled craftsmanship to ensure precision and durability in the final products.

At the core of this process lies the injection moulding technique. This method involves injecting molten plastic into a pre-formed mould to create the desired shape of the pipe fitting. The choice of raw materials, such as thermoplastics or thermosetting plastics, significantly impacts the performance and longevity of the fittings. Thermoplastics, like polypropylene and polyvinyl chloride (PVC), are particularly popular due to their excellent resistance to chemicals and corrosion, making them ideal for various applications.

The design of the mould itself is critical. Engineers and designers utilize computer-aided design (CAD) software to create detailed models that ensure the mould functions efficiently. The precision in the moulding process is essential to achieve tight tolerances, which ultimately affects the performance of the fittings. A well-designed mould reduces waste material, minimizes production time, and enhances the overall quality of the product.

In addition to design and material selection, careful consideration must be given to the cooling and heating systems integrated into the mould. These systems are essential to control the temperature during the injection and solidification processes, ensuring that the plastic flows smoothly into the mould and sets correctly. Proper temperature management can significantly affect the cycle time and the quality of the finished fittings.

Another critical aspect of plastic pipe fittings mould is the maintenance and care of the mould itself. Regular inspection and maintenance are necessary to prolong the lifespan of the mould and ensure consistent product quality. This includes cleaning the mould, checking for wear and tear, and promptly addressing any issues that arise during the production process.

Moreover, advancements in technology, such as the adoption of automation and robotics, are transforming how moulding processes are conducted. These technologies enhance efficiency, reduce human error, and allow for greater flexibility in production. As industries continue to evolve, the importance of plastic pipe fittings mould will only grow, making it a vital area of focus for manufacturers.

In conclusion, understanding the intricacies and importance of plastic pipe fittings mould is essential for anyone involved in the manufacturing process of plastic components. From design and material selection to maintenance and technological advancements, every element contributes to the overall effectiveness and quality of the pipeline systems we rely on today.

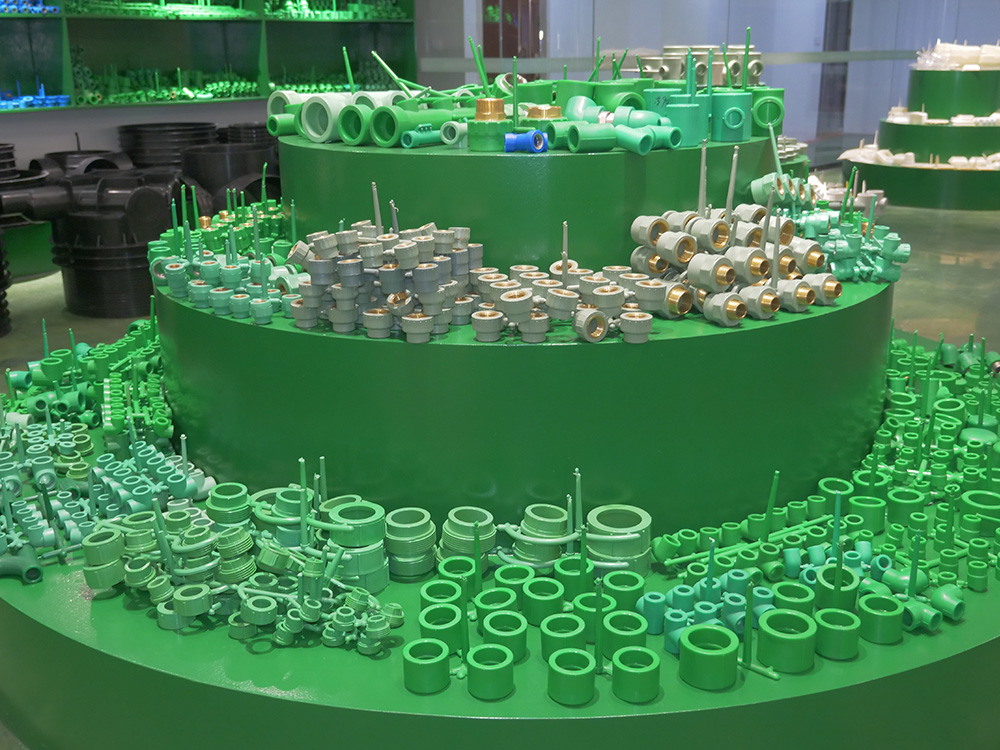

Plastic Pipe Fittings Mould

This website uses cookies to ensure you get the best experience on our website.

Comment

(0)