Understanding PVC Drainage Pipe Fitting Mould: A Key Element in Efficient Manufacturing

In the realm of manufacturing and processing machinery, particularly within the plastic molding sector, PVC drainage Pipe Fitting Moulds play an essential role. These moulds are specifically designed to shape polyvinyl chloride (PVC) materials into various drainage pipe fittings that are integral to modern plumbing and drainage systems. Understanding the intricacies of these moulds can significantly enhance production efficiency and product quality.

PVC is a widely used thermoplastic polymer known for its lightweight properties, resistance to corrosion, and durability, making it an ideal material for drainage systems. The process of creating PVC fittings begins with the design of a fitting mould. This design must accommodate the specifications of the desired fitting shape while ensuring that it can withstand the pressures and environmental conditions typical of drainage applications.

One of the critical factors in the design of PVC drainage pipe fitting moulds is the precision of the moulding process. High-quality moulds allow for the production of fittings that not only meet stringent industry standards but also align perfectly with the corresponding pipes. This precision reduces the risk of leakage and enhances the overall efficiency of drainage systems.

The manufacturing process involves several stages, including mould design, material selection, and production techniques. Advanced computer-aided design (CAD) software is often utilized to create detailed mould designs, ensuring that all dimensions are accurate and functional. Following the design phase, the mould is manufactured, typically from high-strength steel or aluminum, to withstand the wear and tear of repetitive usage over time.

Once the mould is created, it undergoes a testing phase to ensure that it produces fittings that adhere to quality standards. This phase is crucial, as any imperfections in the mould can lead to defects in the final product, potentially resulting in costly repairs or replacements in the field.

In addition to design and manufacturing, it is essential to consider the maintenance of PVC drainage pipe fitting moulds. Regular maintenance ensures the longevity of the mould and maintains the quality of the fittings produced. This might include cleaning, inspection for wear and tear, and, when necessary, refurbishing the mould to extend its life cycle.

In conclusion, PVC drainage pipe fitting moulds are vital components in the plastic forming industry, particularly in producing reliable and efficient drainage solutions. By understanding the design, manufacturing process, and maintenance of these moulds, manufacturers can improve their production processes, resulting in high-quality fittings that meet the demands of modern infrastructure. Knowledge and attention to detail in each stage of the moulding process can lead to significant advantages in manufacturing efficiency and product performance.

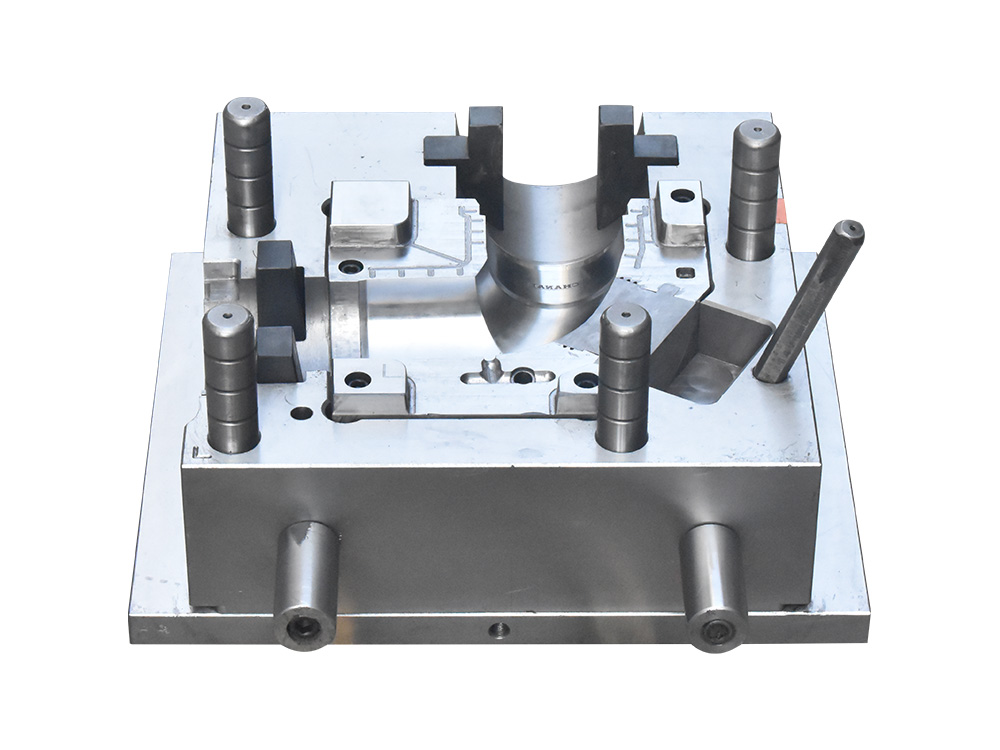

PVC injection molding pipe fitting mould

PVC injection molding pipe fitting mould

This website uses cookies to ensure you get the best experience on our website.

Comment

(0)