Essential Insights into PVC Drainage Pipe Fitting Mould Design

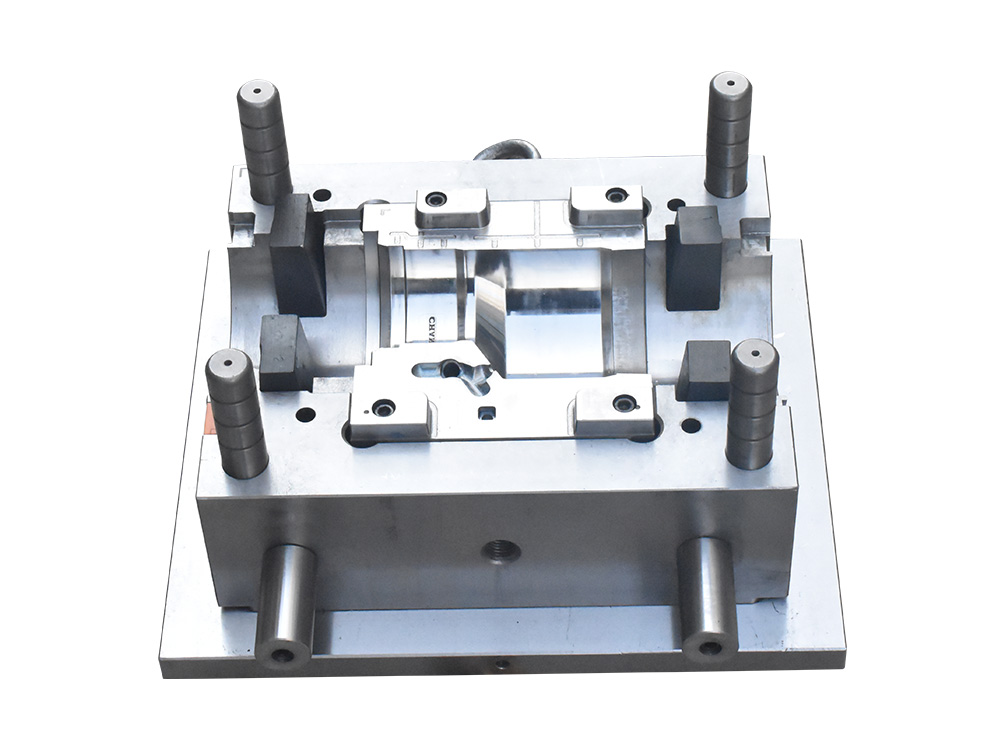

CPVC injection pipe fitting mould

PVC drainage pipes are essential components of modern plumbing and drainage systems. Their effectiveness is largely dependent on the quality of the fittings and the precision of the moulds used in their production. In this article, we will explore the intricate processes involved in the design of PVC drainage pipe fitting moulds, emphasizing best practices, innovative techniques, and the crucial aspects of material selection.

The design of the mould directly influences the quality and performance of the PVC drainage fittings. A well-designed mould ensures that the fittings are produced with precise dimensions, improving their compatibility with pipes and overall system efficiency. Moreover, effective mould design can significantly reduce production costs and time, resulting in better profit margins for manufacturers.

Understanding the essential components of mould design is crucial for achieving optimal results.

Choosing the right materials for mould construction is paramount. Common materials include:

- **Steel**: Known for its durability and ability to withstand high temperatures, steel is often used for high-volume production moulds.

- **Aluminum**: While lighter and easier to machine, aluminum is more prone to wear and is typically used for lower-volume applications.

- **Beryllium Copper**: This material offers excellent thermal conductivity, making it suitable for complex mould designs requiring efficient heat transfer.

Effective mould design involves several key considerations:

- **Geometric Design**: The shape of the mould must accommodate the specific profile of the drainage fitting, ensuring proper fitting and performance.

- **Draft Angles**: Incorporating draft angles in the design facilitates easier removal of the finished product from the mould, minimizing the risk of damage.

- **Ventilation**: Adequate venting is critical to allow trapped air to escape during the injection process, preventing defects.

Efficient temperature control within the mould is essential for maintaining the quality of the PVC fittings. Cooling systems help in reducing cycle times, while heating systems ensure proper material flow.

- **Water Cooling Systems**: These systems circulate water through channels in the mould to dissipate heat quickly.

- **Electric Heating Elements**: Used in conjunction with cooling systems, electric heaters maintain optimal temperatures for specific moulding processes.

Advancements in technology have revolutionized mould design and manufacturing. Key innovations include:

- **3D Printing**: Rapid prototyping through 3D printing allows for quick iterations of mould designs, reducing lead times significantly.

- **CAD Software**: Computer-Aided Design (CAD) tools enable precise modelling and simulation of mould performance before actual production.

- **Simulation Software**: Mold flow analysis helps predict how the molten PVC will fill the mould, identifying potential issues before production begins.

Implementing best practices can greatly enhance mould design efficiency and output.

Creating prototypes allows designers to evaluate the functionality and performance of the mould. Testing different iterations can lead to valuable insights, facilitating improvements before moving to full-scale production.

Regular maintenance is crucial for prolonging the service life of moulds. This includes:

- **Cleaning**: Regularly cleaning the mould prevents build-up of debris and material residues that could affect product quality.

- **Inspection**: Routine inspections help identify wear and tear, allowing for timely repairs.

Designing moulds for PVC drainage fittings comes with its own set of challenges. Some common issues include:

- **Deformation During Cooling**: Inadequate cooling or uneven cooling rates can lead to deformations. Using precise cooling channels can mitigate this issue.

- **Material Flow Issues**: Poor design can cause uneven material flow, leading to weak or defective fittings. Simulation tools can help optimize flow paths.

As technology continues to evolve, several trends are emerging in the mould design industry:

- **Sustainability**: There’s a growing emphasis on designing moulds that minimize waste and utilize eco-friendly materials.

- **Smart Manufacturing**: The integration of IoT and automation in mould design is set to enhance efficiency and precision in production.

In conclusion, the design of PVC drainage pipe fitting moulds is a multifaceted process that requires careful consideration of materials, design strategies, and innovations. By understanding the essential components and adopting best practices, manufacturers can improve the quality and efficiency of their production processes, leading to superior products and increased profitability. The future of mould design looks promising, with advancements in technology paving the way for more sustainable and efficient manufacturing practices.

Choosing materials such as steel for high-volume production or aluminum for lower-volume applications is crucial, depending on specific needs.

Regular maintenance, cleaning, and timely inspections are key to prolonging the life of PVC moulds.

Temperature control is essential for ensuring that the PVC material flows correctly and cures adequately, preventing defects.

3D printing allows for rapid prototyping, enabling quick testing and iterations of mould designs, which reduces lead times.

Common issues include deformation during cooling and material flow problems, which can often be mitigated through careful design and simulation.

This website uses cookies to ensure you get the best experience on our website.

Comment

(0)