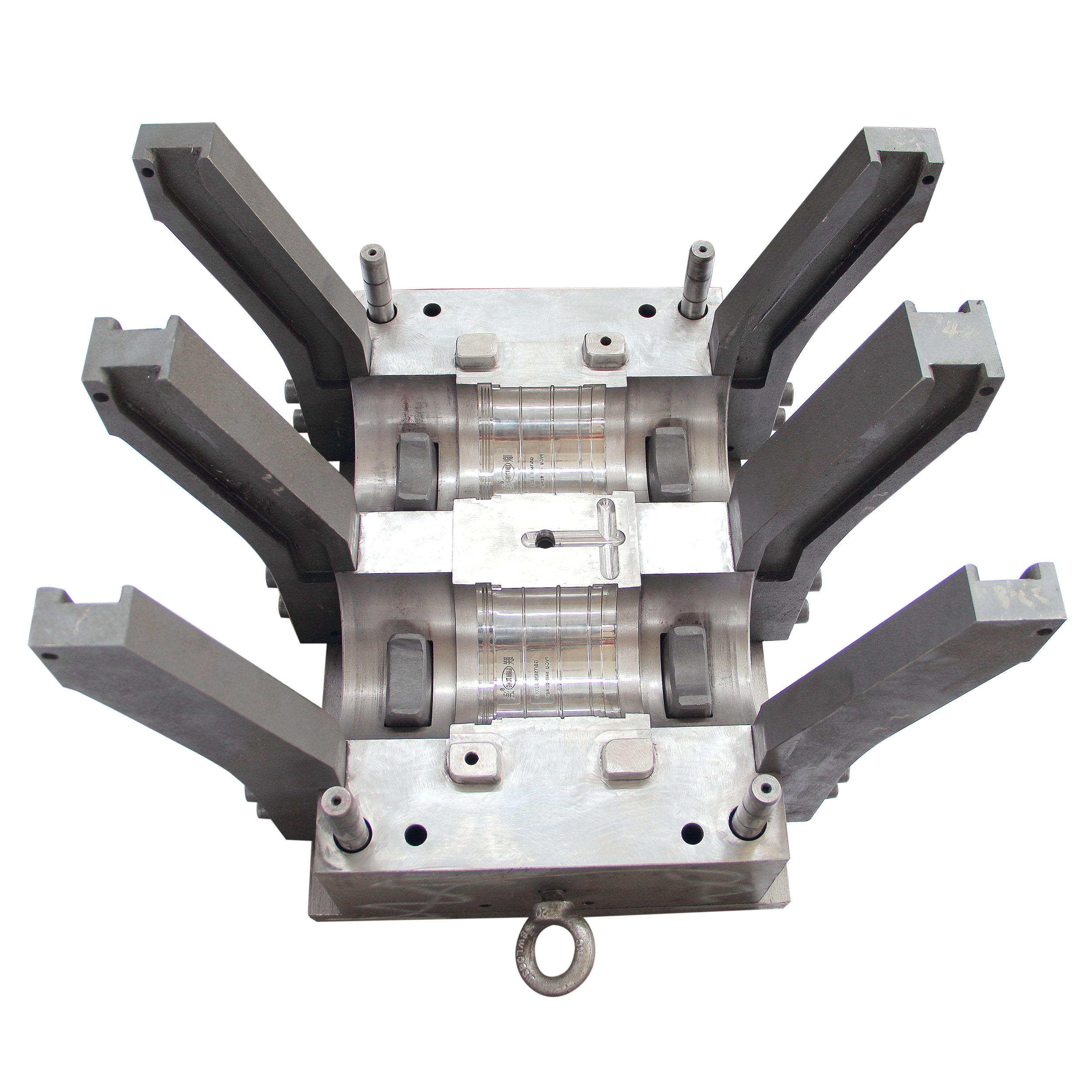

UPVC Socket Pipe Fitting Mould

Mould name: UPVC socket pipe fitting mould

Cavity: 2 cavities

Mould size:110mm

Mould steel:Germany2316 china2316 or4cr13 for the cavity and core

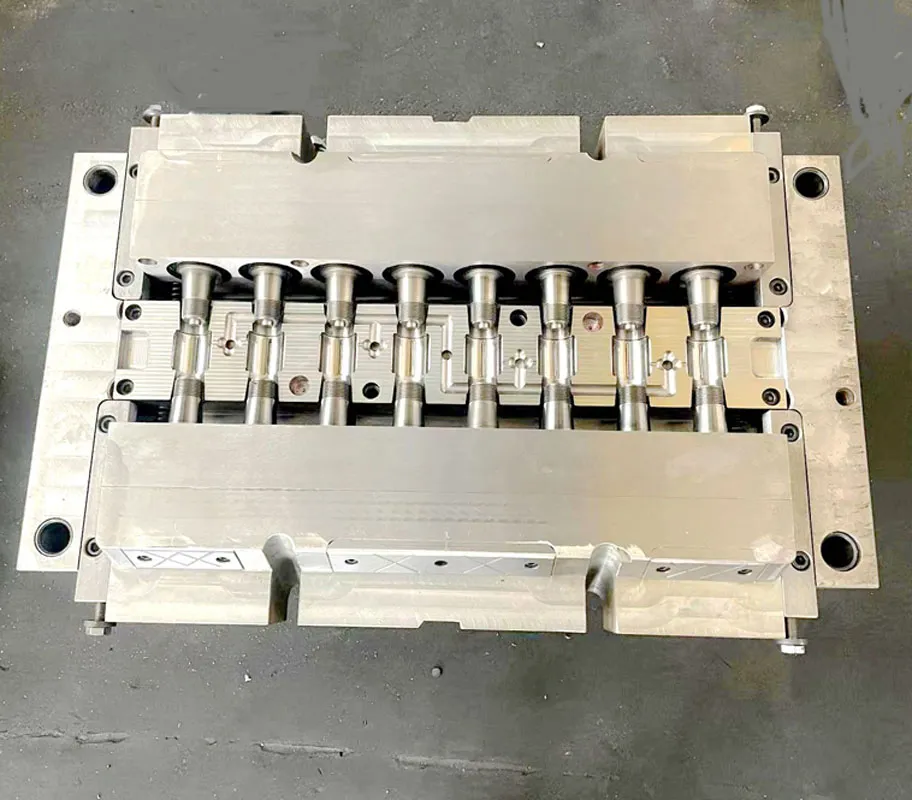

Gate :direct gate

mould structure:cam

Hardness of core/cavity: HRC 40-45°degree after vaccum heat treatment

Injection moulding machine: 320T

Taizhou Huangyan Hong Jin mould Co., Ltd was established in 2002.We are professional in design and manufacture the pipe fitting mould for more than 23 years.

We are looking forward to long cooperation with you.

Following is the main information for your reference.

Difficulties in PVC mold design stage

Complex runner and gate design

Difficulty: PVC melt has high viscosity and poor fluidity. In order to fill all parts of the mold cavity (especially the thin-walled and distal parts) simultaneously and uniformly, the design of the flow channel (main and branch channels) and gate is crucial.

Specific challenges:

Balanced flow channel: Ensure that the pressure drop and flow time from the injection molding machine nozzle to the end of each cavity are consistent, to prevent short injection (insufficient filling) or over pressure holding (overflow, high internal stress) phenomena.

Gate position and form: Improper selection of gate position can cause weld marks to appear in the weak pressure bearing area, seriously affecting the bursting pressure of the pipe fittings. The size of the gate also needs to be accurately calculated. If it is too small, it will generate a large amount of heat during shearing and be prone to decomposition; If it is too large, the cooling will be slow, the cycle will be long, and it will be difficult to remove the gate.

UPVC Socket Pipe Fitting Mould

Cold material well and exhaust: PVC is easy to cool, and an effective cold material well must be designed to capture the front cold material. At the same time, complex cavities are prone to gas entrapment, and it is necessary to set up reasonable and sufficient exhaust slots, otherwise it may cause problems such as burning (decomposition) and material shortage.

Design of cavity and estimation of shrinkage rate

Difficulty: The molding shrinkage rate of PVC is not a fixed value, and it is influenced by various factors such as resin grade, formula (such as filler content), process parameters (temperature, pressure), etc.

Specific challenge: Designers must assign different shrinkage rates to different parts of the mold based on experience and a deep understanding of materials. For example, the shrinkage rate of thick and thin meat is different, and the shrinkage rate along the flow direction and vertical direction is also different. Inaccurate estimation can lead to dimensional deviations in the final product, especially affecting the thread connection size and socket fitting size of the pipe fittings.

Cooling system design

Difficulty: PVC is a heat sensitive material that must be efficiently and uniformly cooled inside the mold.

Specific challenges:

Uniform cooling: Irregular pipe structure and uneven wall thickness result in inconsistent cooling rates. The parts with slow cooling will shrink more, resulting in shrinkage marks, warping deformation, and internal stress.

Waterway layout: It is necessary to arrange cooling waterways as close and balanced as possible to the surface of the mold cavity in complex mold frames and cores, which is a huge test of processing capability. Uneven cooling directly leads to extended production cycles and decreased product yield.

Demoulding system design

Difficulty: PVC fittings usually have internal threads, inverted buckles, or complex rib structures.

Specific challenges:

Core pulling mechanism: Complex sliding blocks, inclined tops, and other core pulling mechanisms need to be designed to achieve demolding. The design of these institutions must be precise, reliable, smooth in motion, interference free, and have sufficient strength and wear resistance.

Top out balance: The layout of the top pin must ensure that the pipe fittings are smoothly and synchronously pushed out. Any imbalance can cause the product to become white, deformed, or even broken.

RELATED

RELATED

RELATED

RELATED

This website uses cookies to ensure you get the best experience on our website.