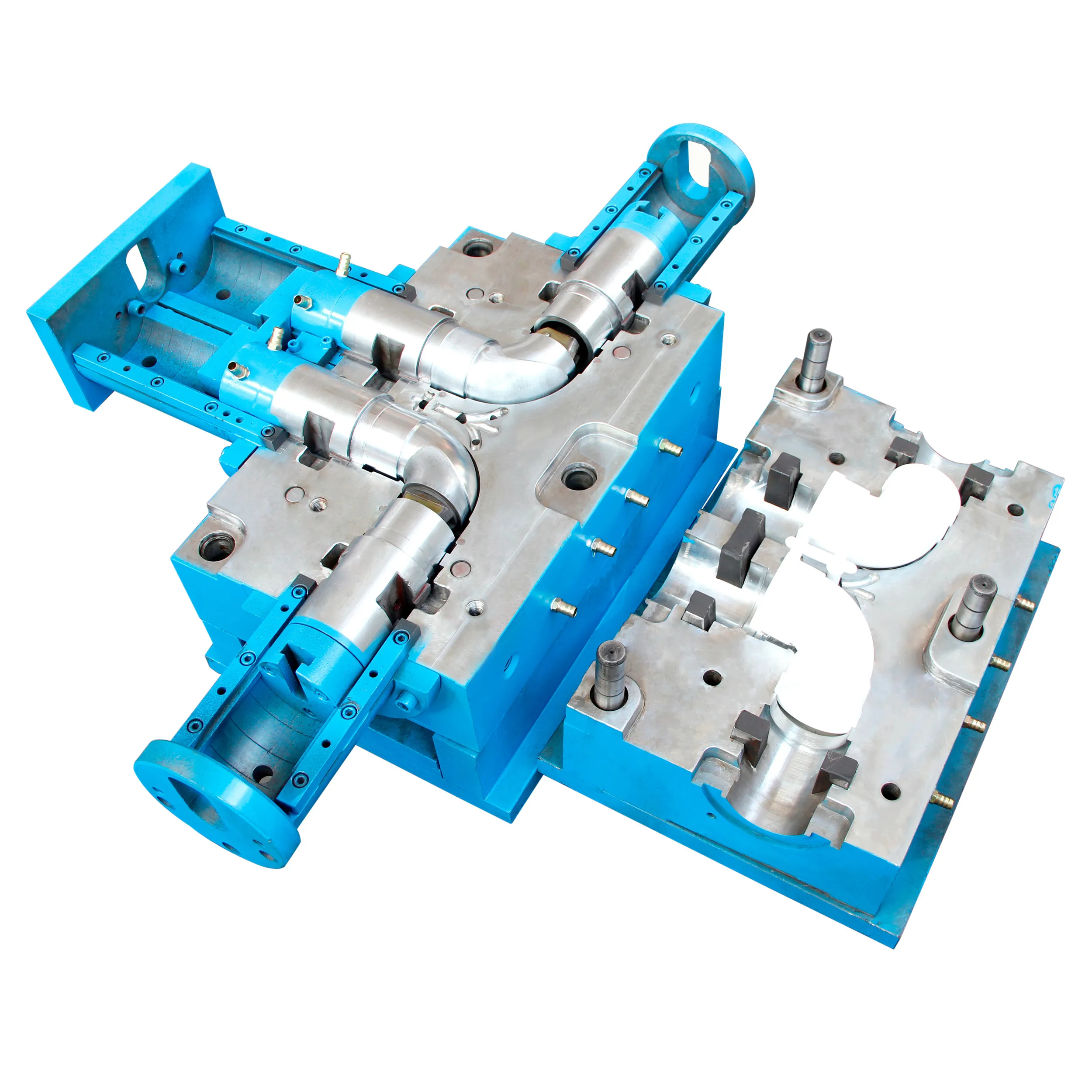

PVC Elbow 90 With Door Pipe Fitting Mould

Mould name: PVC Elbow 90 With Door Pipe Fitting Mould

Cavity: 2 cavities

Mould size:75mm

Mould steel:Germany2316 china2316 or4cr13 for the cavity and core

Gate :direct gate

mould structure:Oil cylinder

Hardness of core/cavity: HRC 40-45°degree after vaccum heat treatment

Injection moulding machine: 320 T

Pvc injection problem and the solution

1. Lack of material:The phenomenon that the mould can not be filled often occurs in the process of injection pipe fittings. When the injection molding machine just started to work, due to the mold temperature is too low, the heat loss of PVC molten material is large, easy to produce early solidification, the resistance of the mold cavity is large, and the material can not be filled with the mold cavity. This phenomenon is very normal, but also temporary, after continuous injection of digital model will automatically disappear. If the mold cannot be filled all the time, consider the following situations and make appropriate adjustments:

1: the temperature of the injection material is low and the fluidity is poor, so the heating temperature can be appropriately raised to improve the plasticization and fluidity of the material.

2: Set injection molding cycle is short, or insufficient material, can be appropriate to increase the injection time and increase the amount of sol.

3: If the set pressure is too low or the time of conversion from injection pressure to holding pressure is too early, the injection pressure can be appropriately increased or the time of conversion from holding pressure can be adjusted.

4: the injection speed is low, the injection speed can be appropriately increased.

5: the flow channel system structure size is small, can be appropriate to increase the volume of the main, shunt channel or the gate to be larger

6: mold exhaust is not good, can be appropriate to modify the gate position or open an exhaust groove.

7: thin wall filling mold is difficult, can adjust the structure of the product or change the gating system.

RELATED

RELATED

RELATED

RELATED

This website uses cookies to ensure you get the best experience on our website.