PP-R Female Brass Pipe Fitting Mould

PP-R Female Brass Pipe Fitting Mould: A Comprehensive Guide

The manufacturing of PP-R (Polypropylene Random Copolymer) pipe fittings requires precision, durability, and efficiency, and the PP-R Female Brass Pipe Fitting Mould plays a pivotal role in this process. This specialized mould is designed to produce high-quality female brass pipe fittings that ensure leak-proof connections, corrosion resistance, and long-term performance in plumbing and HVAC systems.

1. Introduction to PP-R Female Brass Pipe Fittings

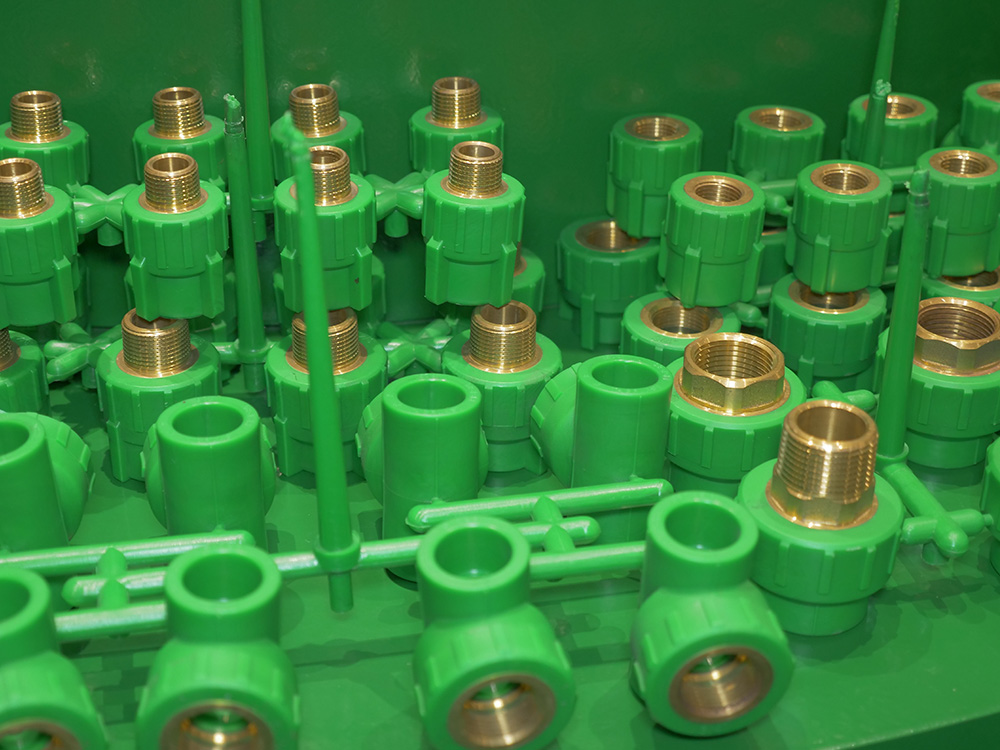

PP-R pipes and fittings are widely used in residential, commercial, and industrial applications due to their excellent thermal resistance, chemical stability, and cost-effectiveness. Female brass pipe fittings, in particular, are essential components that connect PP-R pipes to brass valves, fixtures, or other threaded components. These fittings combine the advantages of PP-R (lightweight, easy installation) with the strength and reliability of brass.

The PP-R Female Brass Pipe Fitting Mould is engineered to produce these fittings with high dimensional accuracy, smooth surfaces, and consistent quality. The mould must withstand high temperatures and pressures during the injection molding process while maintaining tight tolerances.

2. Key Features of PP-R Female Brass Pipe Fitting Mould

A high-quality mould for PP-R female brass fittings should possess the following characteristics:

2.1 Material Selection

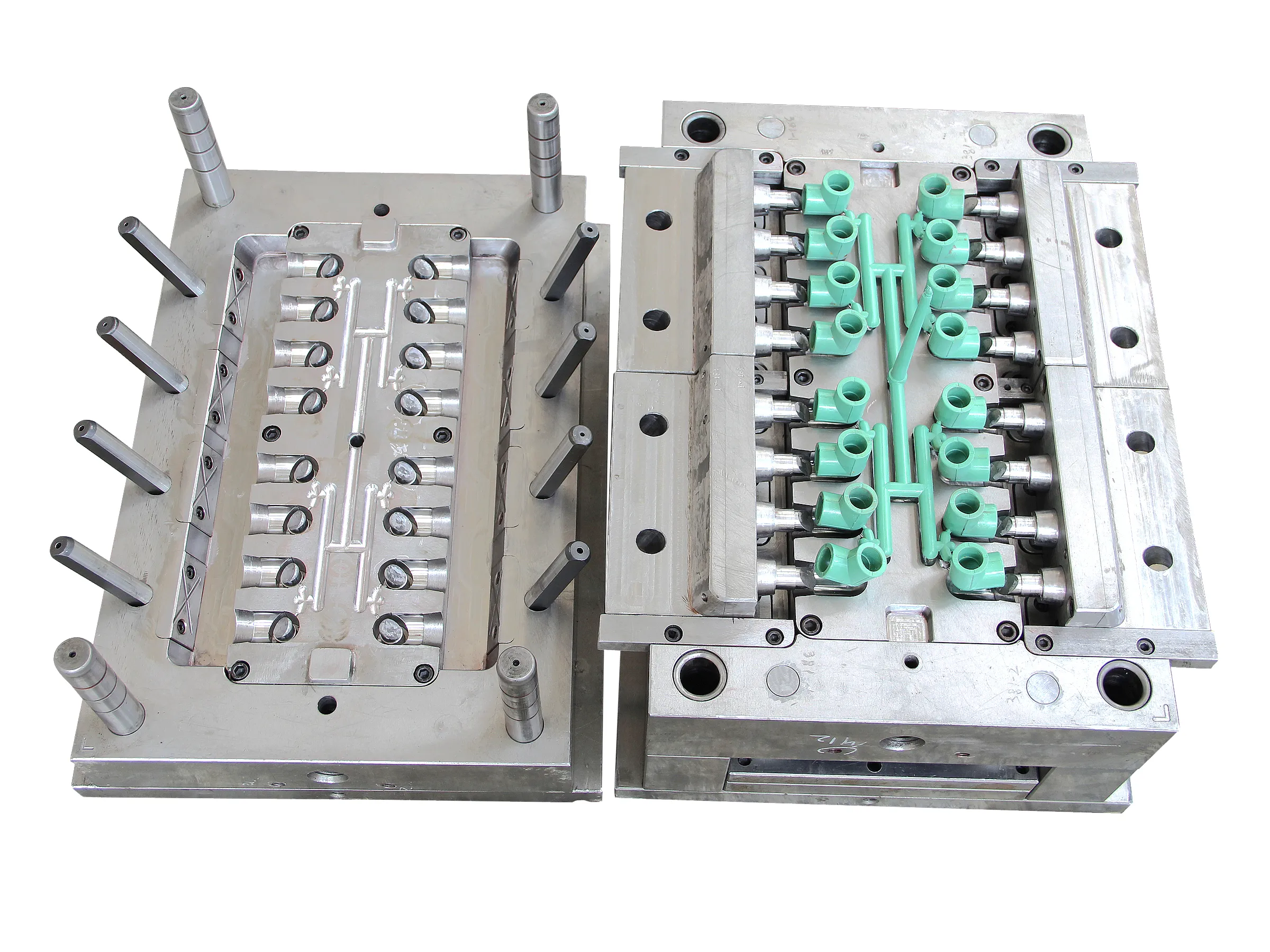

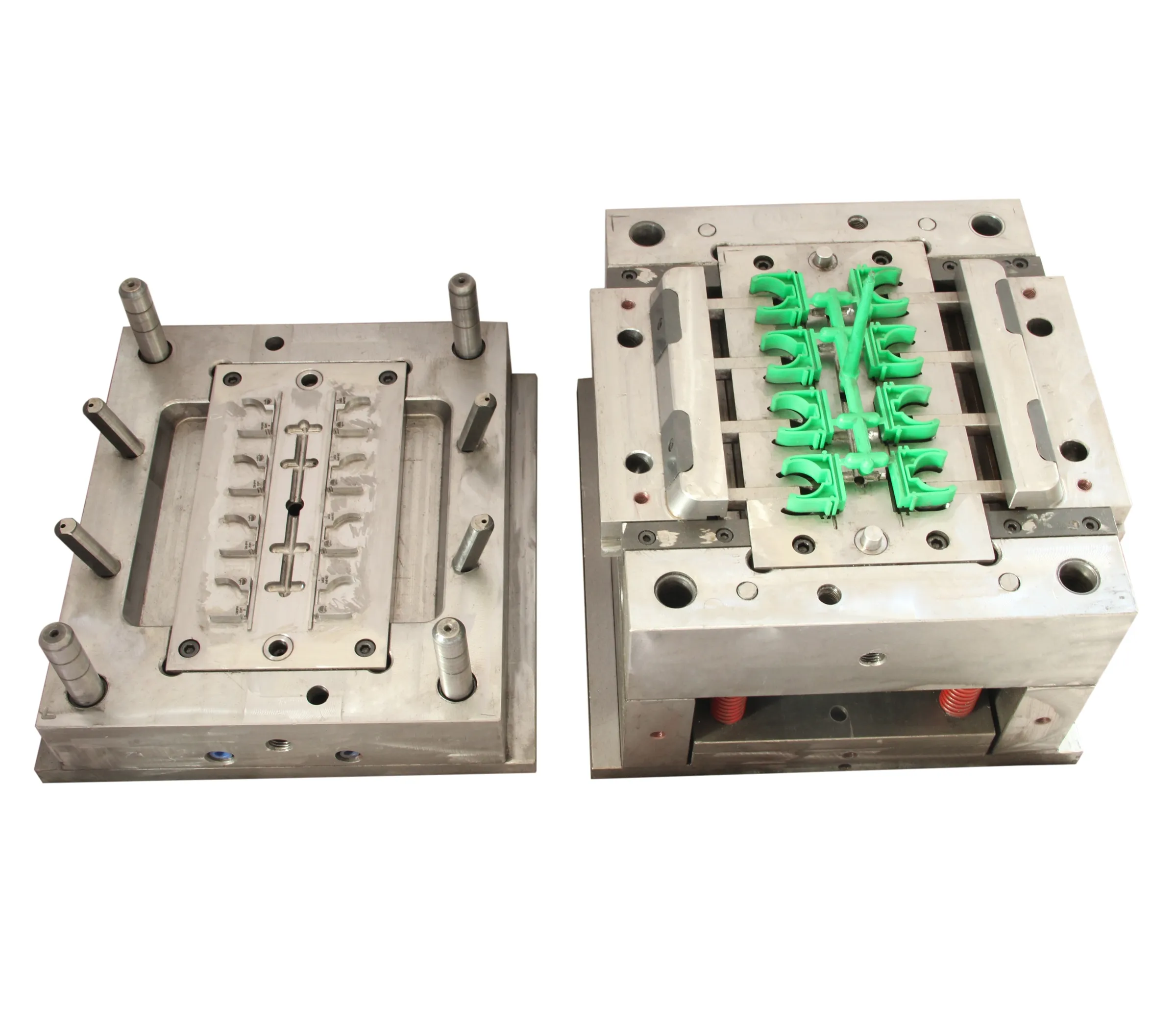

The mould is typically made from high-grade steel, such as H13, P20, or S136, which offers excellent wear resistance, thermal stability, and longevity. The choice of material ensures the mould can endure repeated heating and cooling cycles without deformation.

2.2 Precision Engineering

The mould must be designed with precise cavities and cores to form the intricate threads and sealing surfaces of the female brass fitting. CNC machining and EDM (Electrical Discharge Machining) are commonly used to achieve micron-level accuracy.

2.3 Cooling System Design

An efficient cooling system is critical to reduce cycle times and prevent defects like warping or sink marks. Properly designed cooling channels ensure uniform temperature distribution, enhancing the mould’s lifespan and productivity.

2.4 Venting and Ejection Mechanism

Air traps can cause burn marks or incomplete filling, so the mould must include venting channels. Additionally, an optimized ejection system ensures smooth demolding without damaging the delicate threads of the brass insert.

3. Manufacturing Process of PP-R Female Brass Fittings

The production of PP-R female brass fittings involves several steps:

3.1 Injection Molding

The PP-R material is melted and injected into the mould cavity, where it encapsulates the pre-inserted brass component. The mould must maintain precise alignment to ensure the brass insert is perfectly positioned within the plastic body.

3.2 Cooling and Solidification

After injection, the molten PP-R cools and solidifies around the brass insert. The mould’s cooling system accelerates this process while maintaining dimensional stability.

3.3 Demolding and Finishing

Once cooled, the fitting is ejected, inspected for defects, and subjected to secondary processes like threading verification or pressure testing.

4. Quality Control and Testing

To ensure reliability, PP-R female brass fittings must undergo rigorous testing:

- Dimensional Inspection – Verifies thread accuracy and fitting dimensions.

- Pressure Testing – Confirms leak-proof performance under high pressure.

- Thermal Cycling Tests – Assesses durability under temperature fluctuations.

5. Applications of PP-R Female Brass Pipe Fittings

These fittings are widely used in:

- Plumbing systems (hot and cold water distribution)

- HVAC systems (radiators, underfloor heating)

- Industrial pipelines (chemical transport, compressed air systems)

6. Advantages of Using PP-R Female Brass Fittings

- Corrosion Resistance – Brass inserts resist rust and scaling.

- High Pressure Tolerance – Suitable for demanding applications.

- Easy Installation – Lightweight yet robust.

- Long Service Life – PP-R and brass ensure decades of reliable performance.

7. Challenges in Mould Design and Production

Designing a PP-R Female Brass Pipe Fitting Mould presents several challenges:

- Thread Precision – Brass threads must align perfectly with PP-R encapsulation.

- Thermal Management – Uneven cooling can cause warping or weak spots.

- Mould Maintenance – Regular cleaning and polishing are necessary to prevent wear.

8. Future Trends in PP-R Fitting Mould Technology

Advancements in mould technology include:

- 3D Printing for Prototyping – Faster design validation.

- Smart Moulds with Sensors – Real-time monitoring of temperature and pressure.

- Eco-Friendly Materials – Sustainable steel alloys and coatings.

9. Conclusion

The PP-R Female Brass Pipe Fitting Mould is a critical component in producing high-performance plumbing fittings. Its precision engineering, durable materials, and advanced cooling systems ensure consistent quality and efficiency. As demand for reliable piping solutions grows, continuous innovation in mould technology will further enhance the performance and sustainability of PP-R brass fittings.

By understanding the intricacies of mould design and manufacturing, industry professionals can optimize production processes and deliver superior products for global infrastructure needs.

---

This content provides a detailed overview of the PP-R Female Brass Pipe Fitting Mould without mentioning any specific company, focusing instead on technical aspects, applications, and industry trends. Let me know if you'd like any modifications!

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

This website uses cookies to ensure you get the best experience on our website.